EHV

Rigid duct

Application

EHV is especially suitable for bathrooms and environments that require increased airflow when there are high humidity levels in the room.

The EXHAUSTO EHV extraction unit has a patented humidity control, which uses forced airflow when humidity increases. The unit self-adjusts to normal airflow as humidity decreases. The patented humidity control mechanism is mechanically actuated and requires no power supply or battery. However, models with forced extraction, via an external signal or motion sensor, will require power supply, via a battery or transformer.

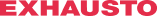

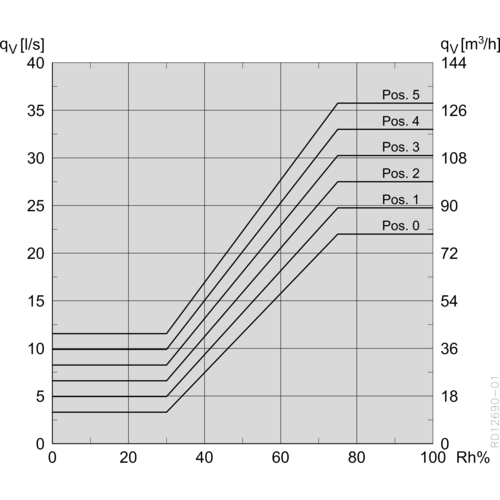

The unit is permanently set to force air when relative humidity reaches 40%. The unit's damper is made of two parts. One half of the damper can be adjusted for six basic levels of airflow. The other half of the damper provides extra forced air. The total airflow is the sum of the basic and the forced airflow.

All EHV valves consist of two damper plates, one permanently fixed for basic ventilation (can be set in positions 0 to 5) and one variable plate controlled by the relative humidity. The humidity-controlled damper plate will start to open at 40% RH and will be fully open at 85% RH.

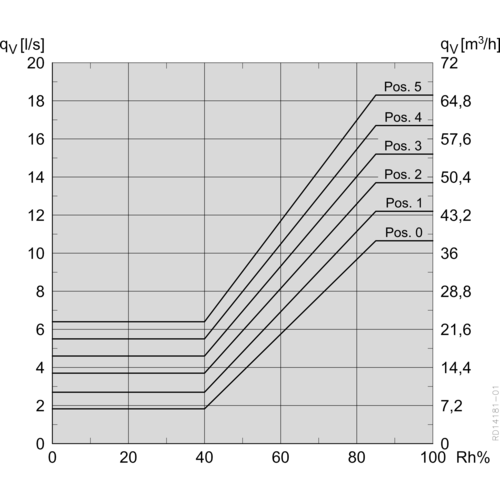

The EHV valve is mounted on the duct (vertically in the wall, horizontally in the ceiling or in a sloping wall). The valve can be mounted using a metal firestop plate (FPP) if needed. FPP also acts as fire protection for duct systems in accordance with DS428 (Fire-technical measures for ventilation units).

- EHV is registered in the database for construction products that can be used in Nordic Swan Ecolabelled construction.

Mount the EHV valve to the wall or ceiling duct with a metal fire protection panel (FPP) which simultaneously protects the duct system in accordance with DS428 (Technical measures for fire protection of ventilation systems).

| Insulation material |

|---|

Setting basic airflow

The fixed damper can be set to six different positions:

- To change the required airflow

- To adjust to the available pressure

The damper is set manually and locked using the supplied locking-pin in order to avoid the damper setting being changed by accident, e.g. during cleaning.

The damper is factory-set to position 0, which is min. airflow.

Moving the damper position down allows a higher airflow.

Each separate step increases airflow by 10 m3/h (maximum = 50 m3/h)

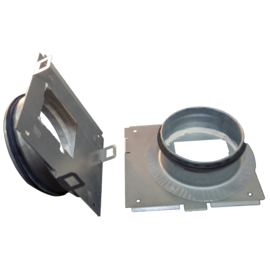

FPP

Panel for fitting to another type of duct opening:

- Rectangular 67 x 75 mm up to 75 x 67 mm

- Round from Ø88 up to Ø100

FPP100

Panel includes spigot with rubber seal for airtight fitting in a Ø100 mm duct.

FPP125

Panel includes spigot with rubber seal for airtight fitting in a Ø125 mm duct.

Balancing the valve in relation to desired airflow step 2:

Register the pressure by fitting a manometer as shown on the illustration.

Look up the initial adjustment diagram in guidance 3004058 (link on right).

Use the registered value to locate the pressure and airflow in relation to the fixed damper position (0-5).