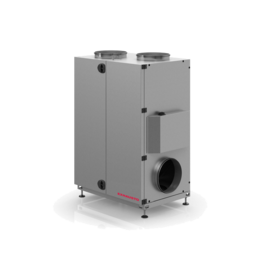

VEX100

CMEV air handling unit

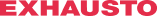

VEX140, 150 and 160 can be ordered in either a Horizontal or Vertical version, whereas VEX170 can only be ordered in Horizontal.

This is a very flexible range of air handling units, which can be ordered as LEFT or RIGHT versions and with spigot locations in the side, top or bottom.

In principle, EXHAUSTO VEX units are designed for use in comfort ventilation - i.e. under ordinary operating conditions.

Product advantages

- Compact units

- Built-in electric or water heating coil

- Flexible spigot positions

- Horizontal and vertical models

- Can be ordered for outdoor installation

VEX100 brings fresh, filtered air into the building and recovers heat from the extract air by means of its highly efficient heating heat exchanger. The incoming air can be heated and/or cooled using a complete range of heating/cooling coils.

VEX100 is suitable for tasks not covered by the Ecodesign Directive and where there is no need for such a high efficiency rating. For instance, for ventilating kitchens, bakeries, etc., where there is typically a surplus of heat but also a requirement for pre-heated supply air to the location.

| References | Motor class in accordance with IEC TS 60034-30-2 | Current overload protection | Conditions | Connection direction | Type of exchanger |

|---|---|---|---|---|---|

| VEX140, horizontal version | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Horizontal |

Crossflow |

| VEX150, horizontal version | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Horizontal |

Crossflow |

| VEX160, horizontal version | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Horizontal |

Crossflow |

| VEX170H | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Horizontal |

Crossflow |

| VEX140, in vertical version | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Vertical |

Crossflow |

| VEX150, vertical version | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Vertical |

Crossflow |

| VEX160, vertical version | IE5 (Ultra Premium Efficiency) |

Built-in |

Conditions:> Density = 1.2 kg/m3> Pressure ratio < 1.11 > Other points in acc. with EC327/2011 (see product instructions) |

Vertical |

Crossflow |

| References | Max. Total efficiency (A-D) (%) | Efficiency level requirements | ECO efficiency level during optimal operating point | Overload protection |

|---|---|---|---|---|

| VEX140, horizontal version | 58,1 |

62N (2015) |

76,2N |

Built-in |

| VEX150, horizontal version | 60 |

62N (2015) |

74,4N |

Built-in |

| VEX160, horizontal version | 57,1 |

62N (2015) |

67,2N |

Built-in |

| VEX170H | 60,4 |

62N (2015) |

66,6N |

Built-in |

| VEX140, in vertical version | 58,1 |

62N (2015) |

76,2N |

Built-in |

| VEX150, vertical version | 60 |

62N (2015) |

74,4N |

Built-in |

| VEX160, vertical version | 57,1 |

62N (2015) |

67,2N |

Built-in |

Conditions:

- Density = 1.2 kg/m3

- Pressure ratio < 1.11

- other points in acc. with EC327/2011 (see product instructions)

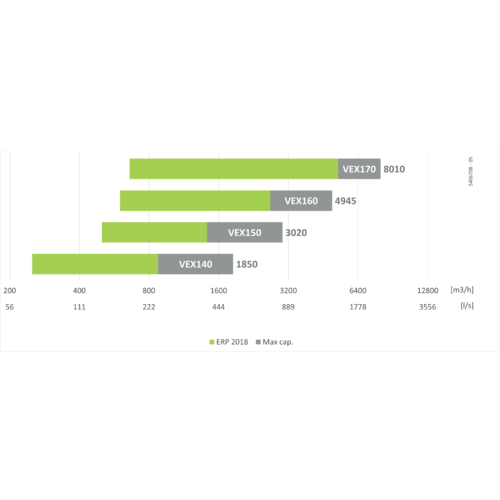

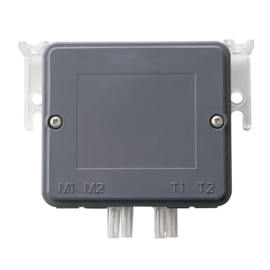

| References | Voltage input | Regulation | Control signal with control system | Control signal with third party control system | Fluid temperature (air) | Ambient temperature range |

|---|---|---|---|---|---|---|

| VEX140, horizontal version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C...+40°C |

-30°C....+50°C |

| VEX150, horizontal version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX160, horizontal version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX170H | 3 x 400 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX140, in vertical version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX150, vertical version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX160, vertical version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

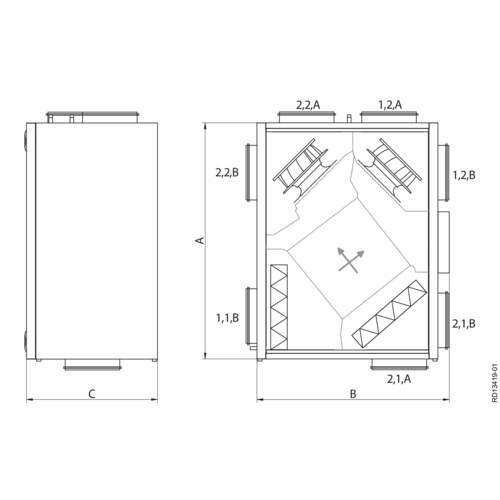

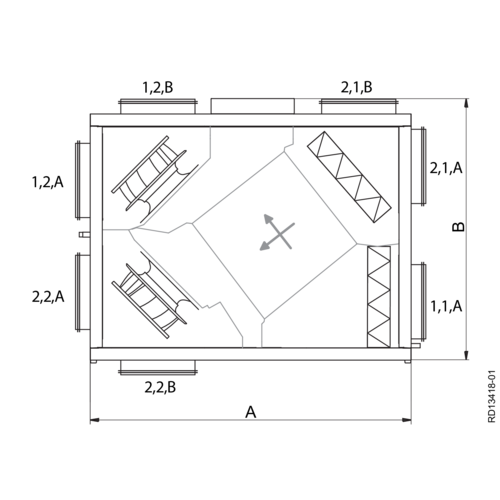

Dimensional drawings for VEX100H = horizontal version and VEX100V– vertical version respectively – both shown with round ducts.

| References | A (mm) | B (mm) | C (mm) | Ø connection (mm) | Weight (kg) | Weight for transport |

|---|---|---|---|---|---|---|

| VEX140, horizontal version | 1365 |

1145 |

750 |

315 |

190 |

105 kg (excl. doors, heat exchanger and fan sections) |

| VEX150, horizontal version | 1600 |

1295 |

835 |

400 |

278 |

164 kg (excl. doors, heat exchanger and fan sections) |

| VEX160, horizontal version | 1820 |

1495 |

940 |

500 |

|

202 kg (excl. doors, heat exchanger and fan sections) |

| VEX170H | 2200 |

1895 |

1240 |

"> with cross-flow heat exchanger type A: 665 kg > with standard cross-flow heat exchanger: 626 kg" |

411 kg (excl. doors, heat exchanger and fan sections) |

|

| VEX140, in vertical version | 1145 |

1365 |

750 |

315 |

190 |

105 kg (excl. doors, heat exchanger and fan sections) |

| VEX150, vertical version | 1600 |

1295 |

835 |

400 |

278 |

164 kg (excl. doors, heat exchanger and fan sections) |

| VEX160, vertical version | 1820 |

1495 |

940 |

500 |

|

202 kg (excl. doors, heat exchanger and fan sections) |

| References | Voltage (V) | Frequency (Hz) | Max. power of electrical coil 1 (kW) | Max. power of electrical coil 2 | Maximum current - unit (A) | Maximum current - first coil (A) | Maximum current - second coil (A) | Max current of zero (A) | Max. electrical output of unit (kW) |

|---|---|---|---|---|---|---|---|---|---|

| VEX140, horizontal version | 1x230 |

50 |

7,2 |

14,4 |

12,5 |

1,6 |

|||

| VEX150, horizontal version | 3x400 |

50 |

7,2 |

14,4 |

8,7 |

26 |

34,7 |

15,0 |

2,7 |

| VEX160, horizontal version | 3x400 |

50 |

14,4 |

21,6 |

15,5 |

36,5 |

46,7 |

23,5 |

4,8 |

| VEX170H | 3x400 |

50 |

31,2 |

46,8 |

17,5 |

62,5 |

85 |

9,2 |

|

| VEX140, in vertical version | 1x230 |

50 |

7,2 |

14,4 |

12,5 |

1,6 |

|||

| VEX150, vertical version | 3x400 |

50 |

12 |

18 |

8,7 |

26 |

34,7 |

15,0 |

2,7 |

| VEX160, vertical version | 3x400 |

50 |

14,4 |

21,6 |

15,5 |

36,5 |

46,7 |

23,5 |

4,8 |

MEKANISK YDEEVNE: In accordance with ds/en 1886 and certified by Eurovent

In accordance with ds/en 1886 and certified by Eurovent:

- Strength of unit housing: D1 (M)

- Tightness at negative pressure of -400 Pa: L1 (M)

- Tightness at positive pressure of +700 Pa: L1 (M)

- Filter bypass leakage: F9 at negative and positive pressure

- Thermal transmittance: T2 (M)

- Thermal bridging factor: TB3

The cabinets are made of Aluzinc AZ185 class C4 according to EN/ISO 12 944-2 and insulated with 50 mm mineral wool. This results in a low noise level to the surroundings/setup room.

The panel construction minimizes the formation of thermal bridges in the unit.

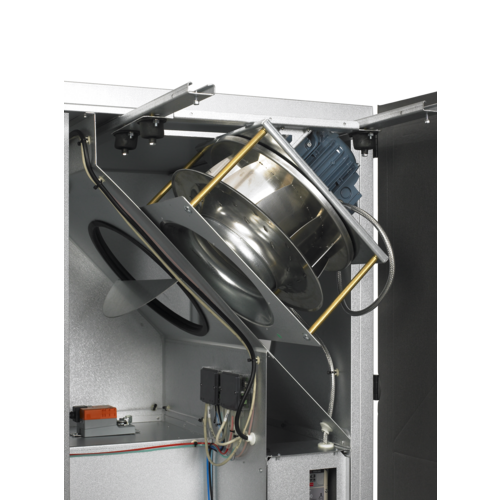

The motor sections are mounted in vibration dampers, which means less noise and vibration in the ducts, and there is no need to install flexible connections between the unit and the duct system.

The motor sections are retractable for easier service.

The motors are EC type with very high efficiency, meeting the requirements of the EcoDesign directive.

The aggregate is equipped with EXHAUSTO's EXstream impeller, one of the market's leading impellers in terms of low energy consumption and low noise level.

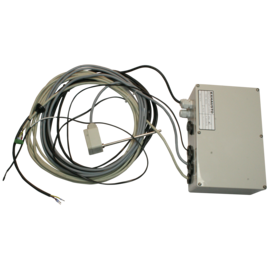

The easily accessible connection box with built-in supply isolator and circuit breakers ensures easy access for connection and adjustment.

The filter panels are easy to replace and can be ordered as filter class Coarse 85% (M5) or ePM1 55% (F7) according to ISO 16890.

VEX100-serien leveres med integreret eftervarmeflade, enten til vand eller el

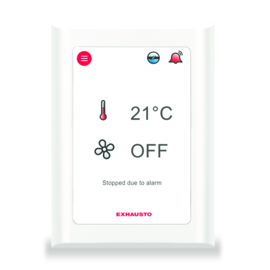

VEX140 - VEX160:

Montagesokkel med fødder, der kan justeres i højden - 130 - 160 mm.

Montagesoklen er standard for VEX170.

VEX100 IS AVAILABLE AS A SPLIT VERSION.

With some projects, limited space means that internal transport of the air handling unit is difficult or impossible. This is why the VEX100 is available as a split version. It means that the air handling unit can be assembled and tested at the factory as normal – just without sealant. The air handling unit can therefore be easily taken apart at the installation site, transported as single sections, assembled, sealed and commissioned.

The table below shows the dimensions of the largest section (crossflow heat exchanger) and largest cabinet section, so that it can easily be determined whether there is sufficient space to allow internal transport.

Products and accessories references

Documents

-

VEX140X-150X-160X-170X, EC Declaration of ConformityConformities127 KB

-

VEX100 EXact2 Declaration of ConformityManuals126 KB

-

VEX140H+V ERP/ECO-design declarationConformities405 KB

-

VEX150H+V ERP/ECO-design declarationConformities357 KB

-

VEX160H+V ERP/ECO-design declarationConformities344 KB

-

VEX170H ERP/ECO-design declarationConformities341 KB

-

VEX, Siphon - pressure side, installation guideManuals641 KB

-

VEX, Siphon - suction side, installation guideManuals633 KB

-

VEX, SiphonHE - frost protection, installation guideManuals598 KB

-

VEX100, order formTechnical & Business documentation639 KB

-

VEX140H with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX150H with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX160H with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX170H with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX140V with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX150V with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX160V with HCE electrical heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX140H with HCW water heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX150H with HCW water heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX160H with HCW water heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX170H with HCW water heating coil and EXact2, mechanical instructionManuals6 MB

-

VEX140V with HCW water heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX150V vertical with HCW water heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX160V with HCW water heating coil and EXact2, mechanical instructionManuals5 MB

-

VEX140H-V-X with HCW water heating coil without controls, , mechanical instructionManuals13 MB

-

VEX150H-V-X with HCW water heating coil without controls, , mechanical instructionManuals4 MB

-

VEX160H-V with HCW water heating coil without controls, mechanical instructionManuals4 MB

-

VEX170H with HCW water heating coil without controls, mechanical instructionManuals4 MB

-

VEX140 with HCW water heating coil and EXact2E, electrical instructionManuals2 MB

-

VEX150-170 with HCW water heating coil and EXact2, electrical instructionManuals4 MB

-

VEX140 with HCW water heating coil without control, electrical instructionManuals1 MB

-

VEX150-160 with HCW water heating coil without control, electrical instructionManuals1 MB

-

VEX170H with HCW water heating coil without control, electrical instructionManuals1 MB

-

VEX140-170 with electrical heating coil HCE and EXact2, electrical instructionManuals5 MB

-

EXact2-HMI2 for VEX100/VEX100CF, instructionManuals3 MB

-

EXact2-HM2 for VEX100/VEX100CF, menu guideManuals632 KB

-

EXact2 menyguide för VEX100/VEX100CFManuals1 MB