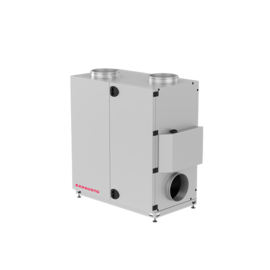

VEX100CF

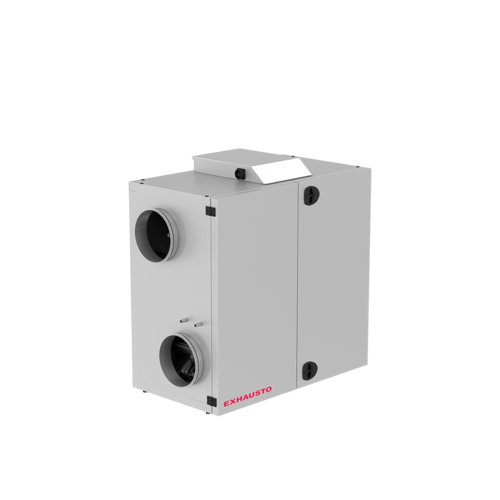

Air handling unit

VEX140CF, VEX150CF and VEX160CF can be ordered as either a Horizontal or Vertical version, whereas VEX170CF can only be ordered as a Horizontal version.

Product advantages

- Compact units with counterflow heat exchanger

- Built-in electric or water heating coil

- Flexible spigot positions

- Horizontal and vertical models

- Can be ordered for outdoor installation

VEX100CF brings fresh, filtered air into the building and recovers heat from the exhaust air using its high-efficiency heat exchanger. The incoming air can be heated and/or cooled using a full range of heating/cooling coils.

The VEX100CF range consists of the tried and tested VEX100 air handling unit, now with counterflow heat exchanger. As a result, this compact and flexible air handling unit will continue to comply with the applicable energy regulations, as VEX100CF is Erp18-compliant. This is a very flexible range of air handling units, which can be ordered as LEFT or RIGHT versions and with spigot locations in the side, top or bottom. VEX140CF, VEX150CF and VEX160CF can be ordered as either a Horizontal or Vertical version, whereas VEX170CF can only be ordered as a Horizontal version. Recommendation As there is a risk of condensate due to the location of the airways, we often recommend the purchase of accessory V100CFCONTUBE (a condensation drain and fitting for the exhaust side).

| References | Motor class in accordance with IEC TS 60034-30-2 | Current overload protection | Connection direction | Type of exchanger |

|---|---|---|---|---|

| VEX140CF, in horizontal version | IE5 (Ultra Premium Efficiency) |

Built-in |

Horizontal |

Counterflow |

| VEX150CF, horizontal version | IE5 (Ultra Premium Efficiency) |

Built-in |

Horizontal |

Counterflow |

| VEX160CFH | IE5 (Ultra Premium Efficiency) |

Built-in |

Horizontal |

Counterflow |

| VEX170CFH | IE5 (Ultra Premium Efficiency) |

Built-in |

Horizontal |

Counterflow |

| in vertical version | IE5 (Ultra Premium Efficiency) |

Built-in |

Vertical |

Counterflow |

| VEX150CF, vertical version | IE5 (Ultra Premium Efficiency) |

Built-in |

Vertical |

Counterflow |

| VEX160CF, vertical version | IE5 (Ultra Premium Efficiency) |

Built-in |

Vertical |

Counterflow |

| References | Max. Total efficiency (A-D) (%) | Efficiency level requirements | ECO efficiency level during optimal operating point | Overload protection |

|---|---|---|---|---|

| VEX140CF, in horizontal version | 58,1 |

62N (2015) |

76,2N |

Built-in |

| VEX150CF, horizontal version | 60 |

62N (2015) |

74,4N |

Built-in |

| VEX160CFH | 57,1 |

62N (2015) |

67,2N |

Built-in |

| VEX170CFH | 60,4 |

62N (2015) |

66,6N |

Built-in |

| in vertical version | 58,1 |

62N (2015) |

76,2N |

Built-in |

| VEX150CF, vertical version | 60 |

62N (2015) |

74,4N |

Built-in |

| VEX160CF, vertical version | 57,1 |

62N (2015) |

67,2N |

Built-in |

Conditions: > Density = 1.2 kg/m3 > Pressure ratio < 1.11 > other points in acc. with EC327/2011 (see product instructions)

| References | Voltage input | Regulation | Control signal with control system | Control signal with third party control system | Fluid temperature (air) | Ambient temperature range |

|---|---|---|---|---|---|---|

| VEX140CF, in horizontal version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX150CF, horizontal version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX160CFH | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX170CFH | 3 x 400 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| in vertical version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX150CF, vertical version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX160CF, vertical version | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| References | A (mm) | B (mm) | C (mm) | Ø connection (mm) | Weight (kg) | Weight for transport |

|---|---|---|---|---|---|---|

| VEX140CF, in horizontal version | 1365 |

1395 |

750 |

315 |

220 |

129 kg (excl. doors, heat exchanger and fan sections) |

| VEX150CF, horizontal version | 1600 |

1545 |

835 |

400 |

330 |

207 kg (excl. doors, heat exchanger and fan sections) |

| VEX160CFH | 1820 |

1745 |

940 |

500 |

410 |

242 kg (excl. doors, heat exchanger and fan sections) |

| VEX170CFH | 2200 |

2050 |

1240 |

760 |

520 kg (excl. doors, heat exchanger and fan sections) |

|

| in vertical version | 1365 |

1395 |

750 |

315 |

220 |

129 kg (excl. doors, heat exchanger and fan sections) |

| VEX150CF, vertical version | 1600 |

1545 |

835 |

400 |

330 |

207 kg (excl. doors, heat exchanger and fan sections) |

| VEX160CF, vertical version | 1820 |

1745 |

940 |

500 |

410 |

242 kg (excl. doors, heat exchanger and fan sections) |

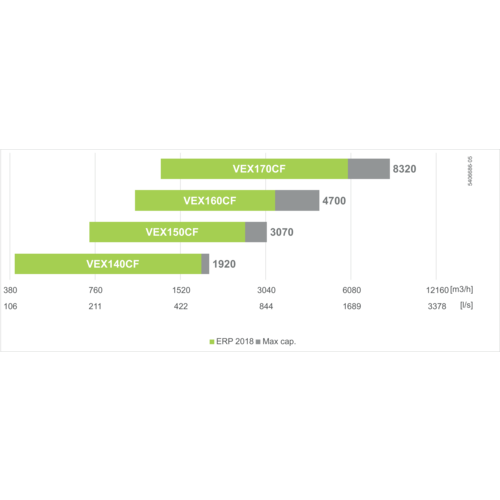

| References | Minimum airflow | Max. airflow ErP (m³/h) | Max. airflow (m³/h) |

|---|---|---|---|

| VEX140CF, in horizontal version | 396 |

1800 |

1920 |

| VEX150CF, horizontal version | 725 |

2575 |

3160 |

| VEX160CFH | 1053 |

3275 |

4680 |

| VEX170CFH | 1296 |

5930 |

8320 |

| in vertical version | 396 |

1800 |

1920 |

| VEX150CF, vertical version | 725 |

2575 |

3160 |

| VEX160CF, vertical version | 1053 |

3275 |

4680 |

| References | Voltage (V) | Frequency (Hz) | Max. power of electrical coil 1 (kW) | Max. power of electrical coil 2 | Maximum current - unit (A) | Max current of zero (A) | Max. electrical output of unit (kW) |

|---|---|---|---|---|---|---|---|

| VEX140CF, in horizontal version | 1x230 |

50 |

7,2 |

14,4 |

12,5 |

1,6 |

|

| VEX150CF, horizontal version | 3x400 |

50 |

12 |

18 |

8,7 |

15,0 |

2,7 |

| VEX160CFH | 3x400 |

50 |

14,4 |

21,6 |

15,5 |

23,5 |

4,8 |

| VEX170CFH | 3x400 |

50 |

31,2 |

46,8 |

17,5 |

9,2 |

|

| in vertical version | 1x230 |

50 |

7,2 |

14,4 |

12,5 |

1,6 |

|

| VEX150CF, vertical version | 3x400 |

50 |

12 |

18 |

8,7 |

15,0 |

2,7 |

| VEX160CF, vertical version | 3x400 |

50 |

14,4 |

21,6 |

15,5 |

23,5 |

4,8 |

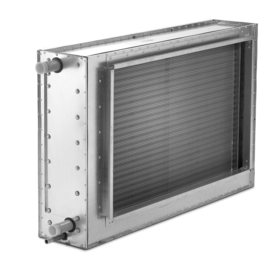

The VEX100CF counter flow heat exchanger is made of aluminium. It is designed to ensure the ratio of heat recovery and pressure loss is at an optimum, i.e. extremely high temperature efficiency is achieved at low levels of energy consumption. - Efficiency level without condensation: 80–85 % - Efficiency with condensation: Up to 94 %

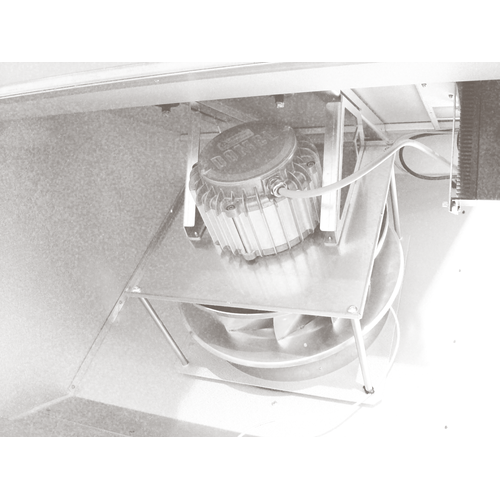

The combination of modern EC motors and the EXHAUSTO motor controller delivers extremely low energy consumption and with the EXstream impeller, a high output is achieved.

An energy label that states the energy class of the unit in relation to defined operating conditions is available via our product calculation programs.

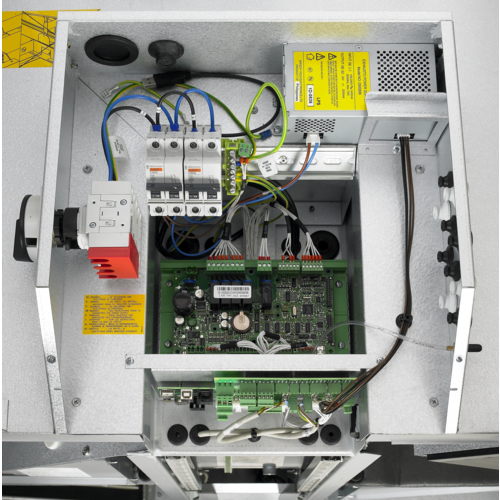

The easily accessible connection box with built-in isolator switch and control fuses ensures easy access for connection and adjustment.

The panel filters are easy to replace and can be ordered as filter class Coarse 85% (M5) or ePM_1 55% (F7) in acc. with EN779.

The VEX100CF range is supplied with an integrated heating coil, heated either by water or electricity

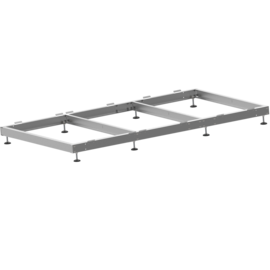

Mounting base is an accessory for VEX140-150-160 and standard on VEX170. The mounting base is equipped with feet that have an adjustable height of 130 - 160 mm.

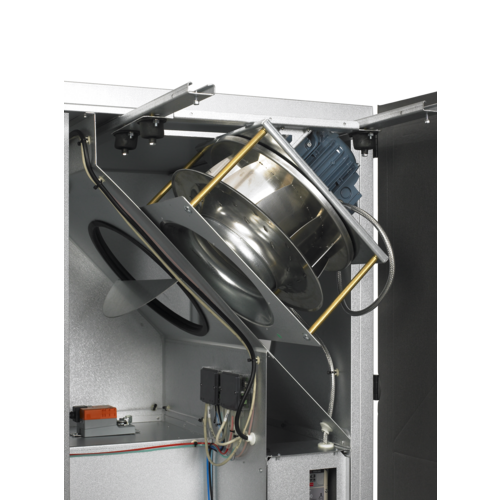

The motor sections are mounted in vibration dampers, which reduces noise in the ducts and eliminates the need to fit flexible connections between the unit and the duct system. The motor sections can be extracted for easier servicing. The motors are of type EC and are extremely efficient. They comply with the requirements of the Ecodesign Directive.

With some projects, limited space means that internal transport of the air handling unit is difficult or impossible. This is why the VEX100CF is available as a split version. It means that the air handling unit can be assembled and tested at the factory as normal – just without sealant. The air handling unit can therefore be easily taken apart at the installation site, transported as single sections, assembled, sealed and commissioned.

The VEX100CF is designed with a de-icing bypass. If there is a risk of icing, then a certain amount of outdoor air will bypass the heat exchanger and go directly to the after heating coil. This increases the demands on the heating coil’s output. However, it avoids a costly preheating coil. The drawing below is an example of a de-icing situation, where 20% of outdoor air is directed through the bypass damper. Heating coil and de-icing function: The de-icing situation is shown above, a heating coil is included here. This is completely necessary, in order for the de-icing function to function correctly. Without the heating coil, the de-icing process would cause the temperature of the supply air to fall, and sooner or later the VEX unit would stop because of icing The heat exchanger has two forms of frost protection: temperature-controlled or pressure-controlled. The actual de-icing can take place in several ways, depending on whether an after heating coil has been fitted.

The control system has temperature-controlled frost protection as standard. It is an inexpensive solution and provides sufficient frost-protection in some situations. A temperature sensor is fitted inside the heat exchanger and if the temperature falls to a pre-set value, de-icing begins. This temperature level is factory set to 0 °C but it can also be changed to a new value via the control system. Temperature-controlled frost protection triggers the de-icing process even if there is no ice in the heat exchanger.

The control system monitors the actual airflow and also the pressure drop across the heat exchanger. If ice forms in the heat exchanger, the pressure drop across the heat exchanger will increase and when it exceeds a pre-set value, de-icing begins. Pressure-controlled frost protection only starts de-icing when ice has actually formed, regardless of whether there are sub-zero temperatures.

Products and accessories references

Documents

-

VEX100CF EXact2, EC Declaration of conformityCertificates and declarations127 KB

-

VEX100CF-X EC declaration of conformityCertificates and declarations126 KB

-

VEX140CF ECOdesign declarationCertificates and declarations344 KB

-

VEX150CF ECOdesign DeclarationCertificates and declarations345 KB

-

VEX160CF ECOdesign declarationCertificates and declarations329 KB

-

VEX170CF ECOdesign declarationCertificates and declarations344 KB

-

VEX100-VEX100CF-VEX200-VEX330-350-360-370 Outdoor InstructionInstructions3 MB

-

VEX, Siphon - pressure side, installation guideInstructions641 KB

-

VEX, assembly on a METU railInstructions358 KB

-

VEX, Siphon - suction side, installation guideInstructions633 KB

-

VEX, SiphonHE - frost protection, installation guideInstructions598 KB

-

VEX100CF Horizontal Contube KitInstructions

-

VEX100CF Vertical Contube KitInstructions3 MB

-

VEX140CF-Horisontal with HCE electrical heating coil and EXact2, mechanical instructionInstructions6 MB

-

VEX150CF-Horisontal with HCE electrical heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX160CF-Horisontal with HCE electrical heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX170CF-Horisontal with HCE electrical heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX140CF-Vertical with HCE electrical heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX150CF Vertical with HCE electrical heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX160CF-Vertical with HCE electrical heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX140CF-Horisontal with HCW water heating coil and EXact2 mechanical instructionInstructions5 MB

-

VEX150CF Horisontal with HCW water heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX160CF Horisontal with HCW water heating coil and EXact2 mechanical instructionInstructions5 MB

-

VEX170CF-Horisontal with HCW water heating coil and EXact2 mechanical instructionInstructions5 MB

-

VEX140CF-Vertical with HCW water heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX150CF-Vertical HCW water heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX160CF Vertical with HCW water heating coil and EXact2, mechanical instructionInstructions5 MB

-

VEX140CF with HCW water heating coil without controls, mechanical instructionInstructions5 MB

-

VEX150CF with HCW water heating coil without controls, mechanical instructionInstructions5 MB

-

VEX170CF with HCW water heating coil without controls, mechanical instructionInstructions5 MB

-

VEX150-170CF with HCW water heating coil and EXact2, electrical instructionTechnical & Business documentation9 MB

-

VEX140CF with HCW water heating coil without control, electrical instructionInstructions3 MB

-

VEX150-160-CF with HCW water heating coil without control, electrical instructionTechnical & Business documentation3 MB

-

VEX170CF with HCW water heating coil without control, electrical instructionInstructions3 MB

-

VEX140-170CF with electrical heating coil HCE and EXact2, electrical instructionTechnical & Business documentation14 MB

-

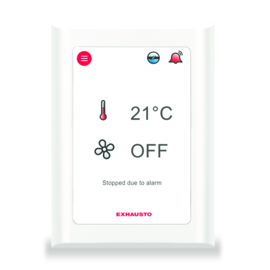

EXact2-HMI2 for VEX100/VEX100CF, instructionInstructions3 MB

-

EXact2-HM2 for VEX100/VEX100CF, menu guideInstructions632 KB