VEX200

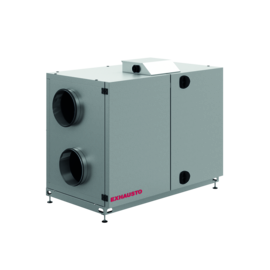

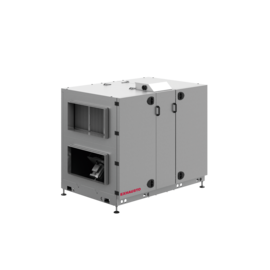

Air handling unit

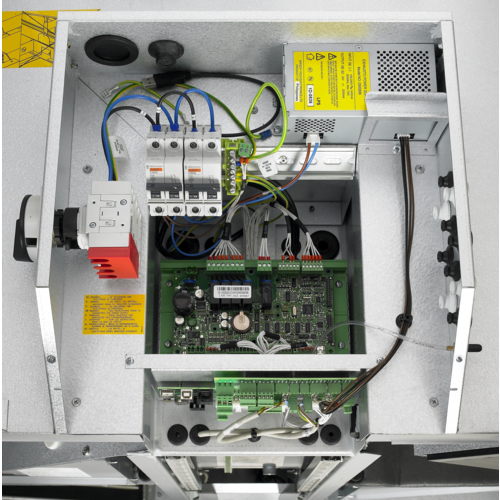

The units are delivered with integrated control systems, that are accessed via the connection box on the front of the air handling unit.

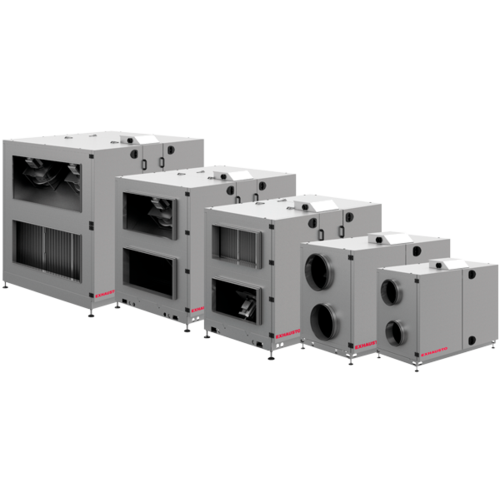

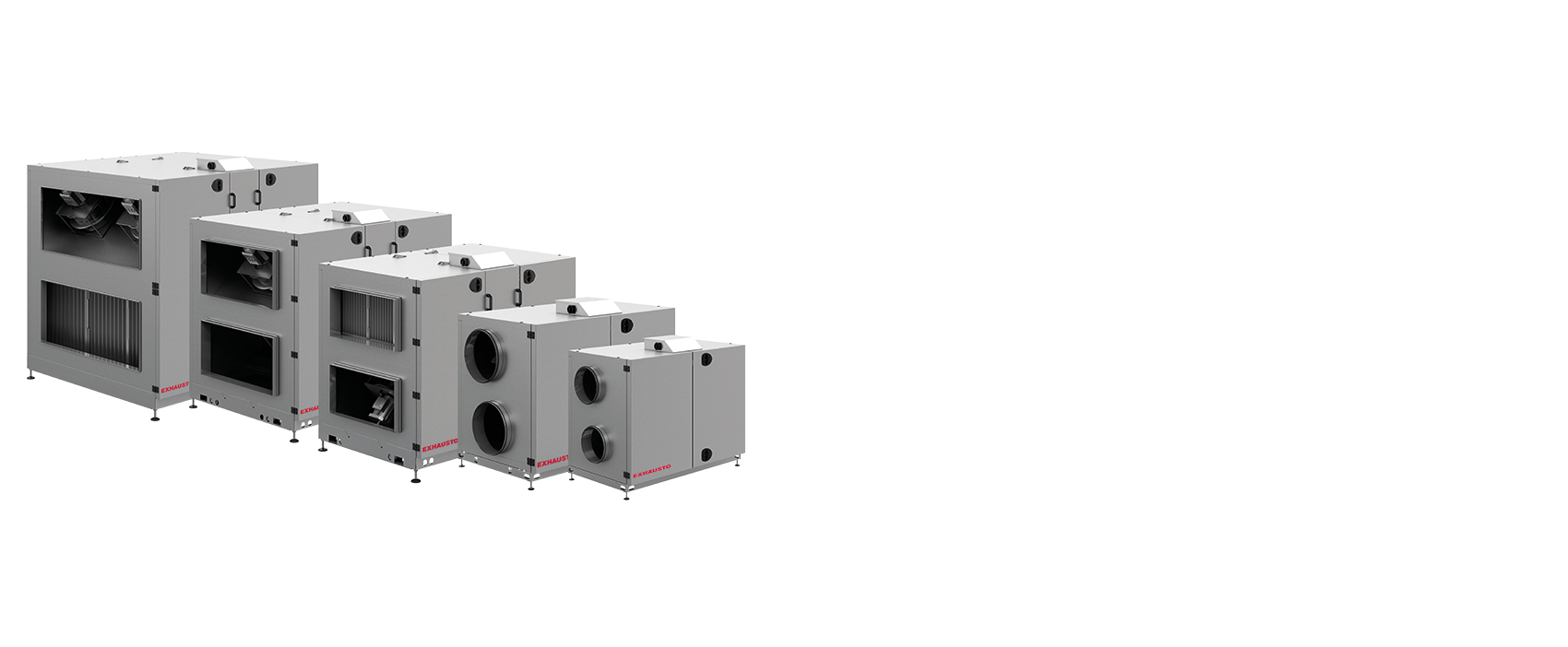

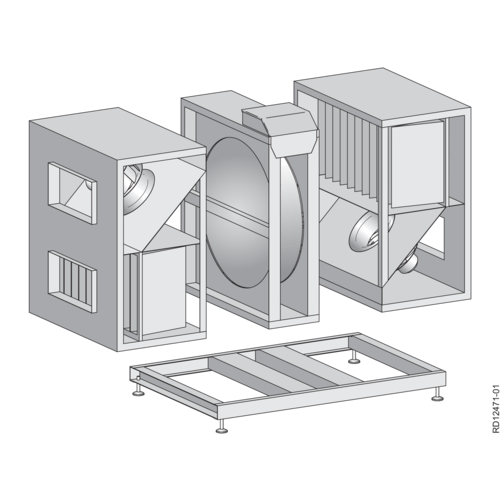

VEX200 air handling units are supplied either as a complete air handling units (VEX240-250) or sectional units (VEX260--280).

Product advantages

- Available as indoor and outdoor model

- Optimal air quality and thermal comfort

- Very low noise level

- Energy savings * Easy installation and maintenance

- New

- Refurbishment

- Non-residential buildings

- Schools

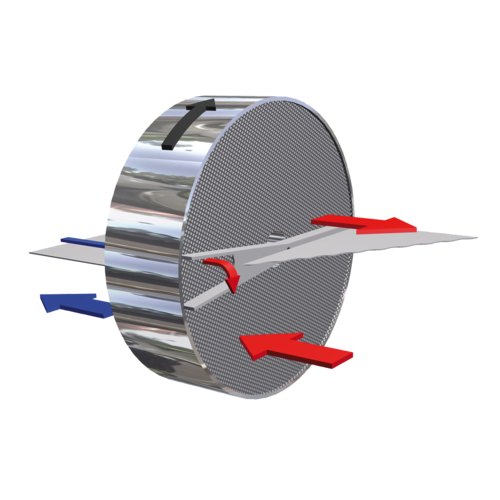

The VEX 200 brings fresh, filtered air into the building and recovers heat from exhaust air using its high-efficiency heat exchanger. The incoming air can be heated and/or cooled using a comprehensive range of coils.

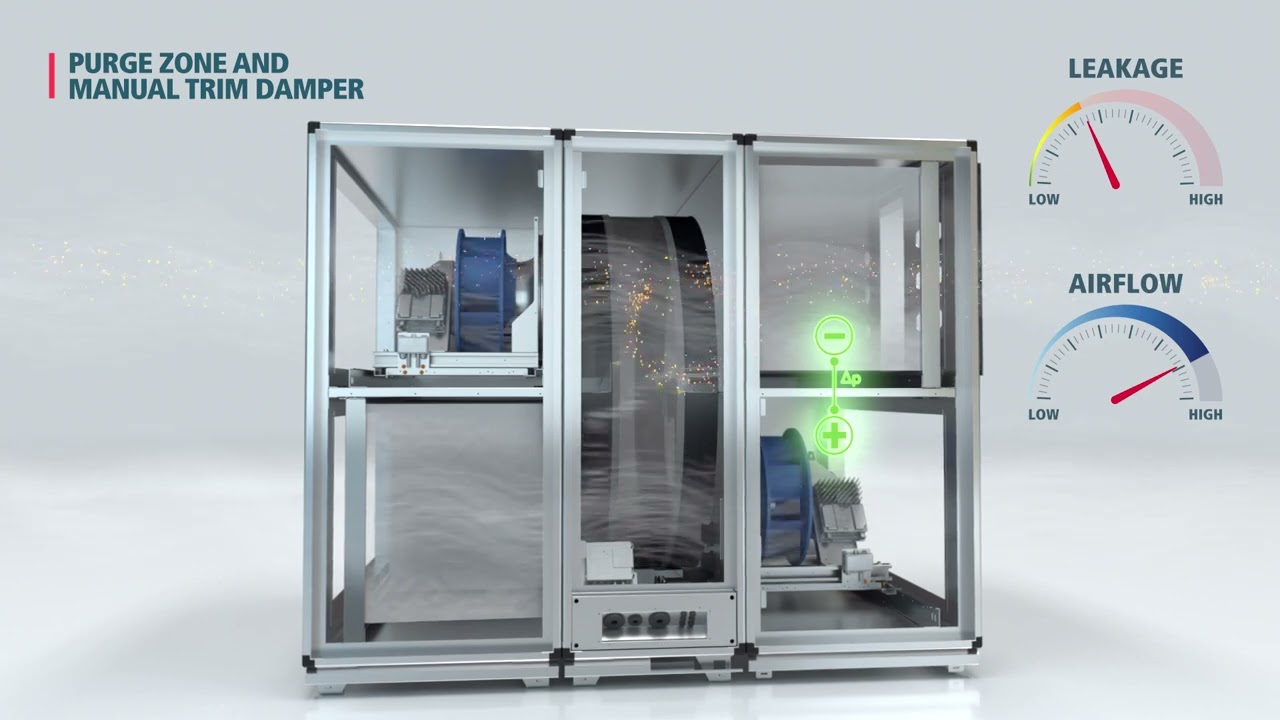

- The ALC™ (Automatic Leakage Control) option is the patented solution that prevents the propagation of viruses by air handling units equipped with rotary heat exchangers. It measures, checks and constantly adjusts the pressure difference between supply and return airflows to ensure that no stale air comes into contact with the clean air produced by the unit.

- Monoblock or multi-block units depending on the model.

- Self-supporting construction with dual-wall panels.

- External finish in Aluzinc AZ185: class 4 anti-corrosion performance.

- 49 mm mineral wool insulation (class A1 as per DIN4102), 65 kg/m³ density.

- EN 1886 values: D2, L2/L2, T2, TB3, F8, F9

- Configurable connections.

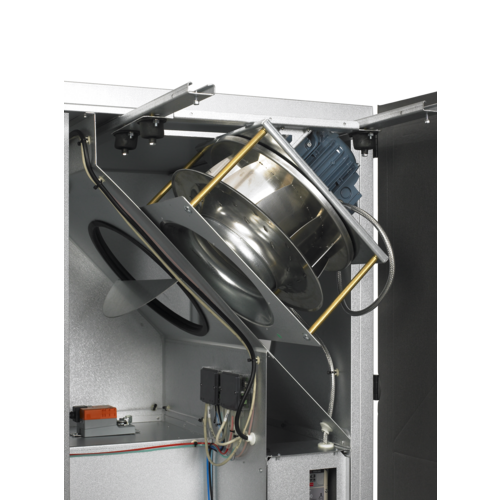

- EC motor and Exstream high-performance backward curve impeller,

- Easy to access and maintain: components mounted on slides, adjustment accessible via a specific central hatch.

- 2 choices of efficiency on rotary exchanger (Eurovent AARE) with optional drain zone to preserve indoor air quality.

- 4 choices of exchanger types on request:

- standard aluminium exchanger,

-

hygroscopic,

- sorption: ideal for hot and humid climates,

- epoxy: ideal for corrosive atmospheres (saline).

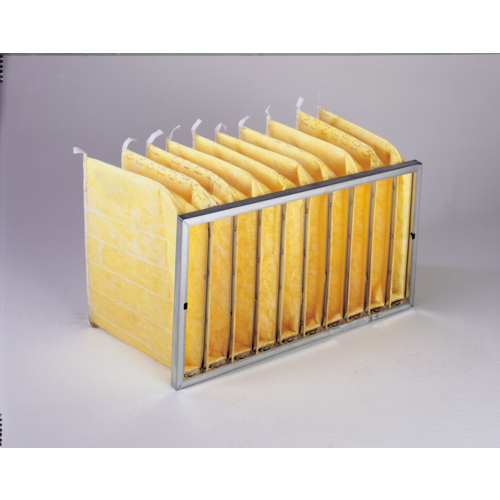

- Choice of filters to guarantee air quality: flat filters or M5 bag filters (ePM10 50%) and F7 (ePM1 65%) - consult us for other types of filters and pre-filters.

- Built-in switch

-

EXact2 controller:

- constant speed,

- multi-speed,

-

constant pressure,

- 0-10 V.

-

Configuration & monitoring via:

- wired remote control,

- option: Webserver and BMS communication via Modbus RTU / RS485, BACnet MSTP / BACnet IP protocols,

- option: Webserver and BMS communication via a gateway supplied to Modbus TCP-IP or LON protocols.

-

Flexible connection to duct system with automatic leakage control (ALC™):

- Horizontal, top and bottom

- Compact design for small rooms – available as a unit or optionally as a SPLIT unit

- equipment rooms / terraces,

- indoors / outdoors,

- in-line duct connection or choice of two vertical fixings,

- connection via circular or rectangular fixings, depending on model,

- choice of left or right side for equipment fittings.

| References | Motor class in accordance with IEC TS 60034-30-2 | Current overload protection | Total pressure (Pa) | RPM during optimal operating point | Conditions | Connection direction | Type of exchanger |

|---|---|---|---|---|---|---|---|

| VEX240 | IE5 (Ultra Premium Efficiency) |

Built-in |

617 |

2886 |

|

Horizontal |

Rotary |

| VEX250 | IE5 (Ultra Premium Efficiency) |

Built-in |

826 |

2902 |

|

Horizontal |

Rotary |

| VEX260 | IE5 (Ultra Premium Efficiency) |

Built-in |

1065 |

3078 |

|

Horizontal |

Rotary |

| VEX270 | IE5 (Ultra Premium Efficiency) |

Built-in |

1396 |

2913 |

|

Horizontal |

Rotary |

| VEX280 | IE5 (Ultra Premium Efficiency) |

Built-in |

1396 |

2913 |

|

Horizontal |

Rotary |

| References | Max. Total efficiency (A-D) (%) | Efficiency level requirements | ECO efficiency level during optimal operating point | EC motor | Overload protection |

|---|---|---|---|---|---|

| VEX240 | 58,1 |

62N (2015) |

76,2N |

Med motorcontroller (VSD) |

Built-in |

| VEX250 | 60 |

62N (2015) |

74,4N |

Med motorcontroller (VSD) |

Built-in |

| VEX260 | 57,1 |

62N (2015) |

67,2N |

Med motorcontroller (VSD) |

Built-in |

| VEX270 | 60,4 |

62N (2015) |

66,6N |

Med motorcontroller (VSD) |

Built-in |

| VEX280 | 60,4 |

62N (2015) |

66,6N |

Med motorcontroller (VSD) |

Built-in |

Conditions:

- Density = 1.2 kg/m3

- Pressure ratio < 1.11

- other points in acc. with EC327/2011 (see product instructions)

| References | Voltage input | Regulation | Control signal with control system | Control signal with third party control system | Fluid temperature (air) | Ambient temperature range |

|---|---|---|---|---|---|---|

| VEX240 | 1 x 230 |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX250 | 1 x 230 |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX260 | 1 x 230 |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX270 | 3 x 400 |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX280 | 3 x 400 |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| References | Rotary stepper motor - Voltage (V) | Rotary stepper motor - Phase current (A) | Rotary stepper motor - Power consumption (W) | Rotary stepper motor - Over-current protection | Rotordrev stepmotor, Control (built in rotation monitor) |

|---|---|---|---|---|---|

| VEX240 | 230 |

0,2 |

45 |

Eingebaut |

Continuously variable from 0 to 10 rpm on the rotor |

| VEX250 | 230 |

0,2 |

45 |

Eingebaut |

Continuously variable from 0 to 10 rpm on the rotor |

| VEX260 | 230 |

0,2 |

45 |

Eingebaut |

Continuously variable from 0 to 10 rpm on the rotor |

| VEX270 | 230 |

0,2 |

45 |

Eingebaut |

Continuously variable from 0 to 10 rpm on the rotor |

| VEX280 | 230 |

0,2 |

45 |

Eingebaut |

Continuously variable from 0 to 10 rpm on the rotor |

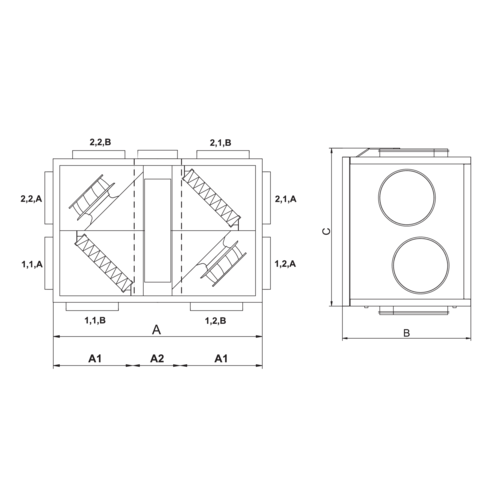

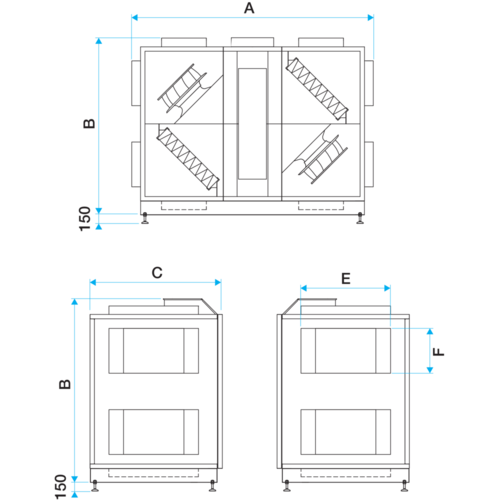

| References | A (mm) | B (mm) | C (mm) | Ø connection (mm) | Weight (kg) | Weight for transport |

|---|---|---|---|---|---|---|

| VEX240 | 1490 |

1050 |

860 |

315 |

260 |

200 kg (excl. doors and fan sections) |

| VEX250 | 1600 |

1100 |

945 |

400 |

273 |

195 kg (excl. doors and fan sections) |

| VEX260 | 1820 |

1370 |

1265 |

525 |

Fan sections: 2 x 117 kgRotor Section: 127,5 kg |

|

| VEX270 | 2050 |

1600 |

1525 |

750 |

Fan sections: 2 x 170,5 kgRotor section: 187 kg |

|

| VEX280 | 2160 |

1900 |

1900 |

1102 |

Fan sections: 2 x 236 kgRotor section: 221 kg |

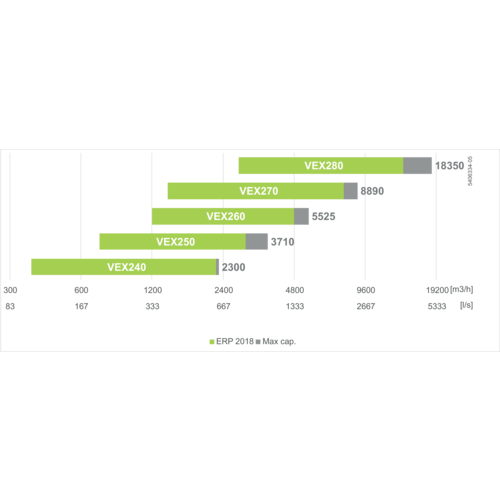

| References | Minimum airflow | Max. airflow ErP (m³/h) | Airflow (m³/h) | Max. airflow (m³/h) |

|---|---|---|---|---|

| VEX240 | 370 |

2090 |

2286 |

2420 |

| VEX250 | 720 |

2825 |

3279 |

3730 |

| VEX260 | 1200 |

4370 |

4551 |

5540 |

| VEX270 | 1400 |

7020 |

7186 |

8910 |

| VEX280 | 2800 |

12615 |

7186 |

18425 |

| References | Max. exchanger output (%) | Max. current absorbed (kW) |

|---|---|---|

| VEX240 | 90 |

12,5 |

| VEX250 | 90 |

11,2 |

| VEX260 | 90 |

18 |

| VEX270 | 90 |

17 |

| VEX280 | 90 |

30,5 |

The aluminium rotary heat exchanger with low pressure drop and a temperature efficiency of 80%.

The rotor control comprises a step motor with motor control.

Efficiency:

- Rotor with wave height of 1.4 mm - very high efficiency

- Rotor with wave height of 1.8 mm - very high efficiency

The combination of modern EC motors and the EXHAUSTO motor controller delivers extremely low energy consumption and with the EXstream impeller, a high output is achieved.

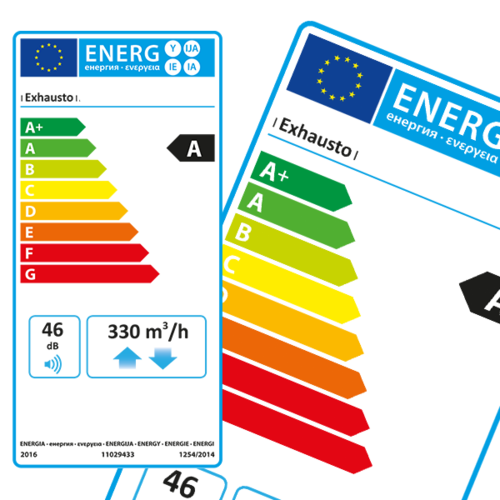

An energy label that states the energy class of the air handling unit in relation to defined operating conditions is available via our product calculation programs.

| References | Voltage (V) | Frequency (Hz) | Max. power of electrical coil 1 (kW) | Max. power of electrical coil 2 | Max. current consumption SINGLE-PHASE 230 V (A) | Max. current consumption THREE-PHASE 400 V (A) | Maximum current - unit (A) | Max current of zero (A) | Max. electrical output of unit (kW) |

|---|---|---|---|---|---|---|---|---|---|

| VEX240 | 1x230 |

50 |

6 |

8 |

12,5 |

12,5 |

1,8 |

||

| VEX250 | 3x400 |

50 |

6 |

12 |

11,2 |

11,2 |

15 |

2,9 |

|

| VEX260 | 3x400 |

50 |

14 |

18 |

18 |

23,5 |

5,0 |

||

| VEX270 | 3x400 |

50 |

21 |

17 |

17 |

9,3 |

|||

| VEX280 | 3x400 |

50 |

46 |

30,5 |

30,5 |

17,6 |

- : Complies with eco-design regulation 1253/2014 and energy labelling regulation 1254/2014 for ventilation. Energy classes:

- : Yes

- : BAT-TH-126

MECHANICAL PERFORMANCE:

According to DS/EN 1886 and certified by Eurovent:

- Casing strength: D1 (M)

- Airtightness under negative pressure at -400 Pa: L1 (M)

- Airtightness under positive pressure at +700 Pa: L1 (M)

- Filter bypass leakage: F9 under negative and positive pressure

- Thermal transmittance: T2 (M)

- Thermal bridging factor: TB3

The cabinets are made from Aluzink AZ185 class C4 and insulated with 50 mm mineral wool. This results in low noise emissions to the external environment/installation location.

The panel construction minimizes the formation of thermal bridges in the air handling unit.

The motor sections are mounted in vibration dampers, which reduces noise in the ducts and eliminates the need to fit flexible connections between the unit and the duct system.

The motor sections can be pulled out for easier servicing.

The motors are of type EC and are extremely efficient. They comply with the requirements of the Ecodesign Directive.

EXstream performance:

The units are equipped with EXHAUSTO EXstream impellers, one of the leading air fan impellers on the market in terms of low energy consumption and low sound level.

The fan impeller rpm and the number of vanes have been optimised so that the “vane frequency” is in the 500 Hz band. This means that fewer/smaller silencers are required than normal and it costs less to sound proof at frequencies of 500 Hz than it does with frequencies of 125/250 Hz (the typical range).

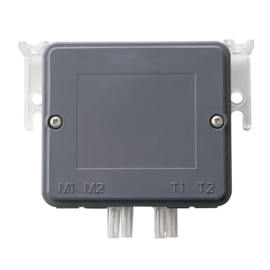

The easily accessible connection box with built-in switch disconnector and control system fuses ensures easy access for connecting and service.

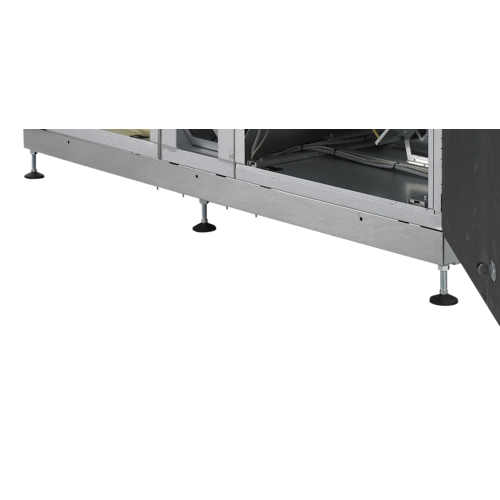

The mounting base has feet with an adjustable height.

The base is an accessory for VEX240/250, but standard on the other models, where the unit is assembled at the bottom by using the base, and via trunk fasteners at the top.

VEX200 series can be supplied with panel filters and bag filters.

Filter class in acc. with EN779:

Panel filters: Coarse 85% (M5) or ePM1 55% (F7)

Bag filters: ePM10 60% (M5) or bag filters ePM1 60% (F7).

With some projects, limited space means that internal transport of the air handling unit is difficult or impossible. This is why the VEX200 is available as a split version. It means that the air handling unit can be assembled and tested at the factory as normal – just without sealant. The air handling unit can therefore be easily taken apart at the installation site, transported as single sections, assembled, sealed and commissioned.

-

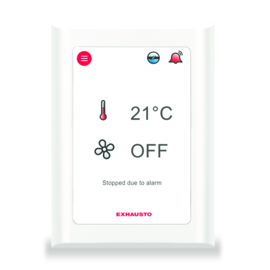

EXact2 control system:

- Constant speed

- Several speeds

- Constant pressure

- 0–10 V

-

Configuration and monitoring via:

- Wired remote control

- Option: Web server and BMS communication via Modbus RTU/RS485, BACnet MSTP/BACnet IP protocols

- Option: Web server and BMS communication via a bridge for Modbus TCP/IP or LON protocols

Documents

-

VEX240-250-260-270-280 EF Declaration of ConformityCertificates and declarations126 KB

-

VEX240X-250X-260X-270X-280X, Declaration of ConformityCertificates and declarations127 KB

-

VEX240H ECOdesign declarationCertificates and declarations347 KB

-

VEX250H ECOdesign declarationCertificates and declarations347 KB

-

VEX260H ECOdesign declarationCertificates and declarations346 KB

-

VEX270H ECOdesign declarationCertificates and declarations347 KB

-

VEX280H ECOdesign declarationCertificates and declarations347 KB

-

VEX170/VEX260-280, transport instructionsTechnical & Business documentation2 MB

-

VEX280 transportation instructionInstructions1 MB

-

VEX100-VEX100CF-VEX200-VEX330-350-360-370 Outdoor InstructionInstructions3 MB

-

VEX200 Blowout-zone and trim damper, installation instructionInstructions2 MB

-

VEX200 Order formTechnical & Business documentation600 KB

-

VEX240H with EXact2, mechanical instructionInstructions2 MB

-

VEX250H with EXact2, mechanical instructionInstructions2 MB

-

VEX270H with EXact2, mechanical instructionInstructions3 MB

-

VEX240-HX without controls, mechanical instructionInstructions3 MB

-

VEX250-HX without controls, mechanical instructionInstructions3 MB

-

VEX260-HX without controls, mechanical instructionInstructions3 MB

-

VEX270-HX without controls, mechanical instructionInstructions3 MB

-

VEX240-250H with EXact2, electrical instructionTechnical & Business documentation2 MB

-

VEX260-270-280H with EXact2, electrical instructionTechnical & Business documentation3 MB

-

VEX280H with EXact2, mechanical instructionInstructions3 MB

-

VEX280-HX without controls, mechanical instructionInstructions3 MB

-

HCE electrical heating coil for VEX280 with EXact2, mechanical instructionInstructions565 KB

-

HCE electrical heating coil for VEX280 without controls, mechanical instructionInstructions585 KB

-

VEX240-250-HX without controls, electrical instructionInstructions2 MB

-

VEX260-270-280-HX without controls, electrical instructionTechnical & Business documentation3 MB

-

EXact2 for VEX200, instructionInstructions4 MB

-

EXact2 for VEX200, menu guideInstructions671 KB

-

VEX280 Repair instructionsInstructions7 MB

-

VEX200, assembly and installation of ALCInstructions9 MB

-

VEX, assembly on a METU railInstructions358 KB

-

VEX100-VEX200-VEX300-VEX4000-VEX5000-DEX3000-CX3000 Industry EPDCertificates and declarations772 KB