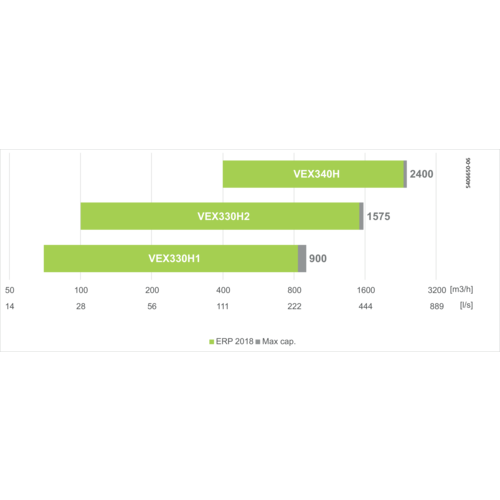

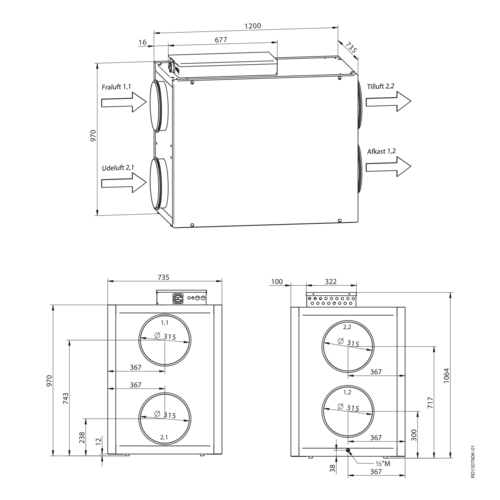

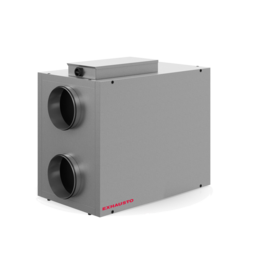

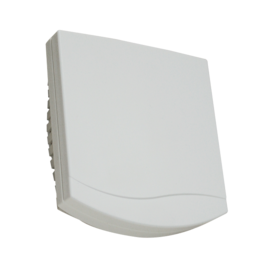

VEX330H

Air handling unit

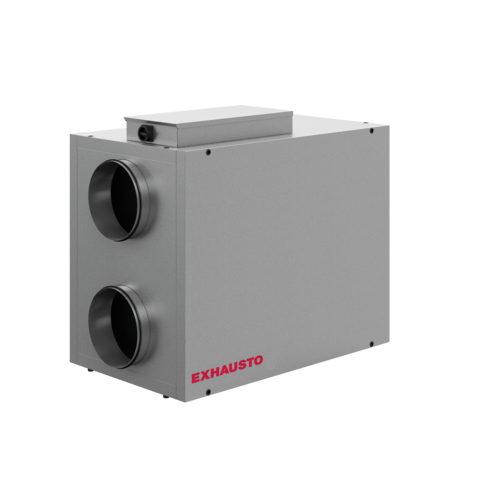

The VEX330H is ideal for residential ventilation, where the air is separated via the ventilation system, removing the risk of odours and humidly being transferred.

Product advantages

- Compact, high-performance unit

- Same unit, Left/Right

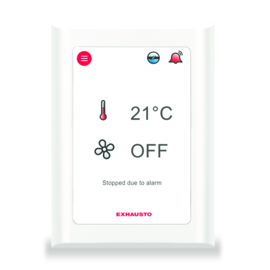

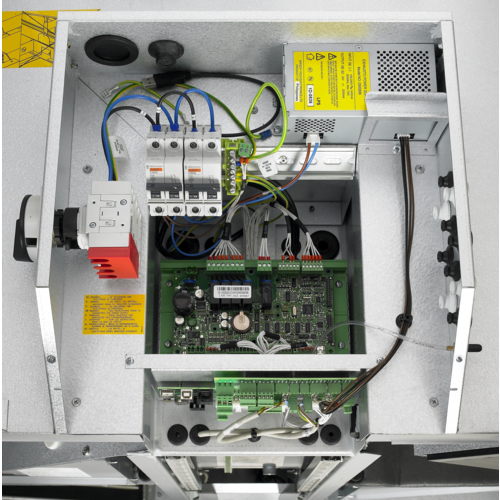

- EXact2, advanced control system

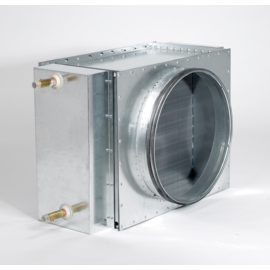

- Water or electric heating coil

- Can be ordered for outdoors installation

- Low sound level

In principle, EXHAUSTO VEX units are designed for use in comfort ventilation - i.e. under ordinary operating conditions.

Where ventilation solutions are required for rooms with high air humidity - e.g. due to humidification, we recommend you make a test calculation with one of our calculation programs. If the calculation shows a risk of condensation after the heat exchanger, an assessment must be made whether the operating conditions can be changed, or whether the unit must be modified to allow condensate to drain off. This is particularly relevant for VEX100CF.

Contact EXHAUSTO for advice on this.

| References | Max. Total efficiency (A-D) (%) | Efficiency level requirements | ECO efficiency level during optimal operating point | Overload protection |

|---|---|---|---|---|

| VEX330H1 | 60,1 |

62N (2015) |

78,7N |

Built-in |

| VEX330H2 | 60,1 |

62N (2015) |

73,7N |

Built-in |

Conditions:

- Density = 1.2 kg/m3

- Pressure ratio < 1.11

- other points in acc. with EC327/2011 (see product instructions)

MECHANICAL PERFORMANCE:

According to DS/EN 1886 and certified by Eurovent:

- Strength of the unit casing: D1 (M)

- Leakage at -400 Pa negative pressure: L1 (M)

- Leakage at +700 Pa positive pressure: L1 (M)

- Filter bypass leakage: F9 at negative and positive pressure

- Thermal transmission: T2 (M)

- Thermal bridging factor: TB3

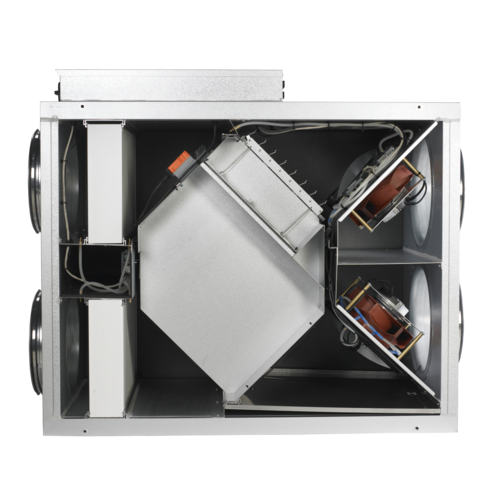

Cabinets are made from Aluzinc® AZ185 class C4 in accordance with EN/ISO12944-2 and insulated with 50 mm mineral wool. This results in low noise emissions to the surrounding environment/installation room.

The panel design minimises the formation of thermal bridges in the unit.

The motor sections are mounted in vibration dampers, which reduces noise in the ducts and eliminates the need to fit flexible connections between the unit and the duct system.

The motors are of type EC and are extremely efficient. They comply with the requirements of the Ecodesign Directive.

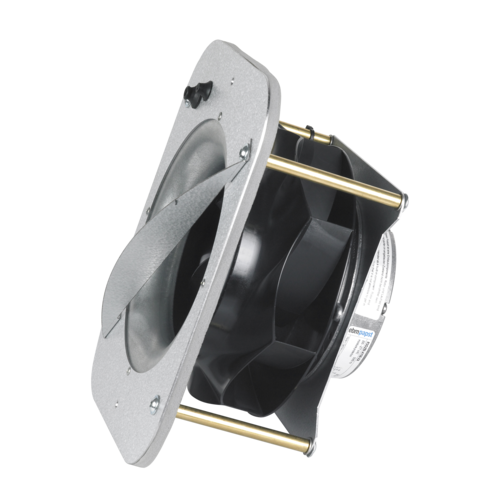

VEX300H is equipped with an optimised centrifugal fan impeller with backwards curved vanes. The impeller design delivers high output with low energy consumption.

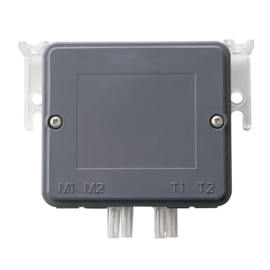

The easily accessible connection box with built-in switch disconnector ensures easy access for connecting and adjusting.

Panel filters are easy to replace and can be ordered as Coarse 85% (M5) or ePM1 55% (F7) in acc. with EN779.

Filter size: 340 x 630 x 96 mm

The side panels on both sides of VEX330H models can be removed (easy access). This allows the unit to function as both a LEFT and RIGHT version.

The unit can also be ordered as an outdoor model. The outdoor unit has a fitted cover that protects it against wind and weather.

The VEX330H is designed with de-icing bypass. If there is a risk of icing, then a certain amount of outdoor air will bypass the heat exchanger and go directly to the after heating coil. This increases the demands on the heating coil’s output. However, it avoids a costly preheating coil. The drawing below is an example of a de-icing situation, where 20% of outdoor air is directed through the bypass damper.

The control system has temperature-controlled frost protection as standard. It is an inexpensive solution and provides sufficient frost-protection in some situations.

A temperature sensor is fitted inside the heat exchanger and if the temperature falls to a pre-set value, de-icing begins. This temperature level is factory set to 0 °C but it can also be changed to a new value via the control system.

Temperature-controlled frost protection triggers the de-icing process even if there is no ice in the heat exchanger.

The control system monitors the actual airflow and also the pressure drop across the heat exchanger. If ice forms in the heat exchanger, the pressure drop across the heat exchanger will increase and when it exceeds a pre-set value, de-icing begins.

Pressure-controlled frost protection only starts de-icing when ice has actually formed, regardless of whether there are sub-zero temperatures.

Products and accessories references

Documents

-

VEX330T Ecodesign DeclarationCertificates and declarations347 KB

-

VEX, Siphon - pressure side, installation guideInstructions641 KB

-

VEX, Siphon - suction side, installation guideInstructions633 KB

-

VEX, SiphonHE - frost protection, installation guideInstructions598 KB

-

VEX330H with EXact2, mechanical instructionInstructions2 MB

-

VEX330H with EXact2, electrical instructionInstructions3 MB

-

VEX330H-X without controls, electrical instructionInstructions906 KB

-

VEX330H without controls, mechanical instructionInstructions3 MB

-

EXact2 HMI2 for VEX300, instructionInstructions6 MB

-

EXact2 HMI2 for VEX300, menu guideInstructions1 MB