VEX340H

CMEV air handling unit

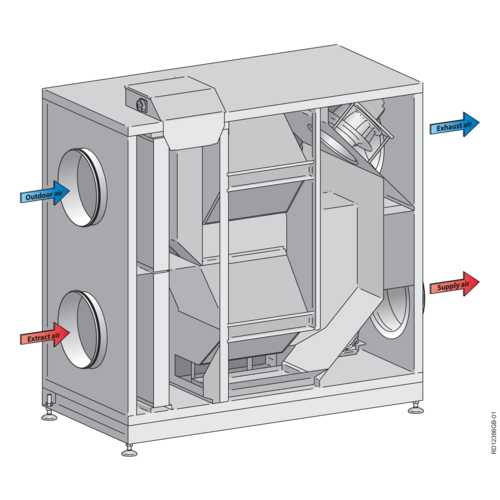

The VEX340H is ideal for residential ventilation, where the air is separated via the ventilation system, removing the risk of odours and humidly being transferred.

The VEX340H size enables it to be transported through a 90 x 200 cm door opening.

In principle, EXHAUSTO VEX units are designed for use in comfort ventilation - i.e. under ordinary operating conditions.

Where ventilation solutions are required for rooms with high air humidity - e.g. due to humidification, we recommend you make a test calculation with one of our calculation programs. If the calculation shows a risk of condensation after the heat exchanger, an assessment must be made whether the operating conditions can be changed, or whether the unit must be modified to allow condensate to drain off.

Contact EXHAUSTO for advice on this.

SPLIT:

For some projects, the space conditions can make it difficult or impossible to transport the unit. Therefore, VEX340H can be ordered as SPLIT. This means that the unit is built and tested at the factory as usual - just without sealing. Therefore, the unit can be easily disassembled at the installation site, carried in parts, assembled, sealed, and commissioned.

| Motor class in accordance with IEC TS 60034-30-2 | Current overload protection | Connection direction | Type of exchanger |

|---|---|---|---|

| IE5 (Ultra Premium Efficiency) |

Built-in |

Horizontal |

With plates |

| References | Max. Total efficiency (A-D) (%) | Efficiency level requirements | ECO efficiency level during optimal operating point | Overload protection |

|---|---|---|---|---|

| VEX340H | 58,1 |

62N |

76,2N |

Built-in |

Conditions:

- Density = 1.2 kg/m3

- Pressure ratio < 1.11

- other points in acc. with EC327/2011 (see product instructions)

| Voltage input | Regulation | Control signal with control system | Control signal with third party control system | Fluid temperature (air) | Ambient temperature range |

|---|---|---|---|---|---|

| 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

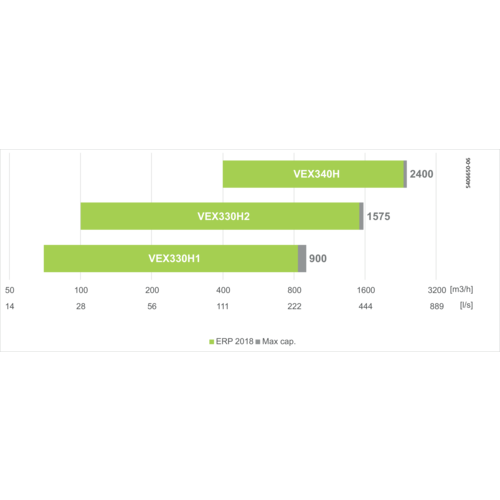

| Minimum airflow | Max. airflow ErP (m³/h) | Max. airflow (m³/h) |

|---|---|---|

| 400 |

2325 |

2450 |

| Voltage (V) | Frequency (Hz) | Maximum current - unit (A) | Max. electrical output of unit (kW) |

|---|---|---|---|

| 1x230 |

50 |

12,5 |

1,8 |

MECHANICAL PERFORMANCE:

According to ds/en 1886 and certified by Eurovent

- Casing strength: D1 (M)

- Leakage at negative pressure of -400 Pa: L1 (M)

- Leakage at positive pressure of +700 Pa: L1 (M)

- Filter bypass leakage: F9 at negative and positive pressure

- Thermal transmittance: T2 (M)

- Thermal bridging factor: TB3

An energy label that states the energy class of the unit in relation to defined operating conditions is available via our product calculation programs.

The motor sections are mounted in vibration dampers, which reduces noise in the ducts and eliminates the need to fit flexible connections between the unit and the duct system.

The motor sections can be extracted for easier servicing.

The motors are of type EC and are extremely efficient. They comply with the requirements of the Ecodesign Directive.

EXstream performance

The unit is equipped with EXHAUSTO’s EXstream fan wheel, one of the market's leading fan wheels in terms of low energy consumption and low noise level.

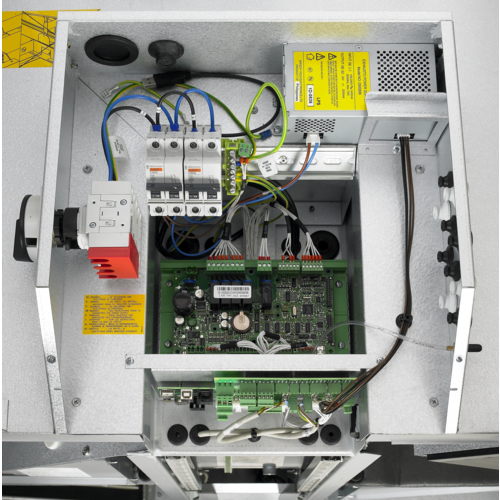

The easily accessible connection box with built-in supply isolator and circuit breakers ensures easy access for connection and adjustment.

The panel filters are easy to replace and can be ordered as Coarse 85% (M5) or ePM1 55% (F7) according to EN779.

Filter size: 716 x 836 x 96 mm.

VEX340 is supplied as standard on a mounting base with feet.

High-efficiency counter flow heat exchangers can suffer icing, especially if the extracted room air is humid. When the energy from this extracted air is used (when the air cools), the moisture condenses to water vapour, which collects in the heat exchanger.

The high efficiency means that some areas inside the heat exchanger become very cold and in these areas condensed water will freeze and form ice. This can block the air flow.

To ensure EXHAUSTO counter flow heat exchangers can operate in areas that have temperatures below -3 °C EXHAUSTO has developed a return air system. When ice begins to form inside the counter flow heat exchanger, the VEX340H control system circulates up to 30 % of the warmed air back into the cold supply air. This raises the temperature of the outdoor air and the problem of icing is reduced.

Air regulation – there are seven different air regulation methods:

Airflow control

2. Constant airflow

Constant pressure regulation of extract air

3. Constant pressure regulated extract air with preset supply air

5. Constant pressure regulated extract air with slave-controlled supply air

Constant pressure regulation of supply air

4. Constant pressure regulated supply air with preset extract air

6. Constant pressure-controlled supply air with slave-controlled extract air

Constant pressure regulation of both extract air and supply air

7. Constant pressure regulation of both extract air and supply air

8. External control of fan speeds

NB! This function is only active for air regulation methods 2 and 5.

Products and accessories references

Documents

-

VEX340H ECOdesign declarationManuals342 KB

-

VEX, Siphon - pressure side, installation guideManuals641 KB

-

VEX340 transport instructionsManuals701 KB

-

VEX340 PHCE-HK Electric preheaterManuals5 MB

-

VEX, Siphon - suction side, installation guideManuals633 KB

-

VEX, SiphonHE - frost protection, installation guideManuals598 KB

-

VEX340-370, order formTechnical & Business documentation280 KB

-

VEX340H-X without controls, mechanical instructionManuals3 MB

-

VEX340H-X without controls, electrical instructionManuals2 MB

-

VEX340H with EXact2, mechanical instructionManuals3 MB

-

VEX340H with EXact2, electrical instructionManuals2 MB

-

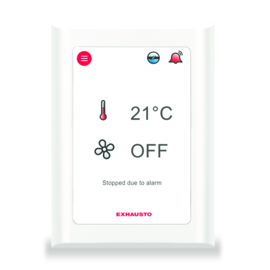

EXact2 HMI2 for VEX300, instructionManuals6 MB

-

EXact2 HMI2 for VEX300, menu guideManuals1 MB

-

VEX, assembly on a METU railManuals358 KB