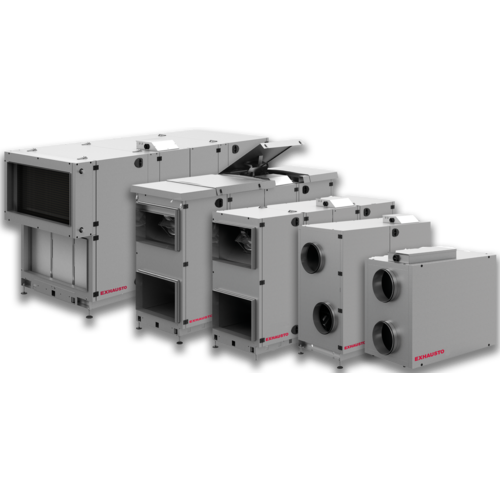

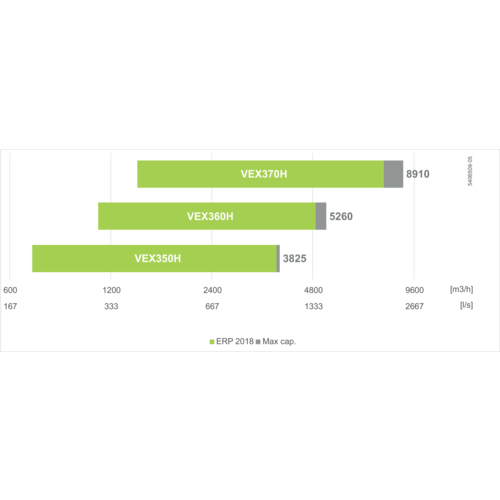

VEX350/360/370H

Air handling unit

The design of the air handling units ensures they have a maximum temperature efficiency and a very low SFP figure.

The VEX units have the great benefit of being modular, which means that the VEX350 and VEX360 can be transported through door openings as small as 900 x 2000 cm, and therefore be split into sections.

Product advantages

- Unique energy-saving design with double bypass

- Can be ordered as outdoor version

- Can be transported through a 90-cm wide door, VEX370 only in SPLIT 1 version

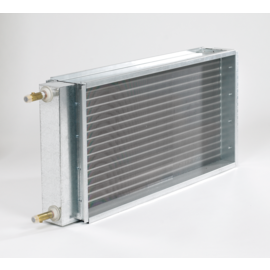

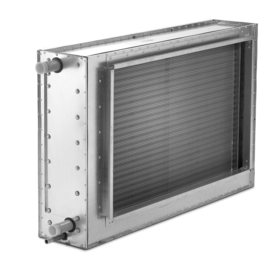

- Various heating and cooling coil solutions, VEX370 also with integrated water heating coil

- Compact units

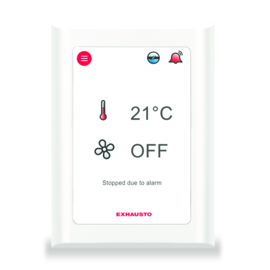

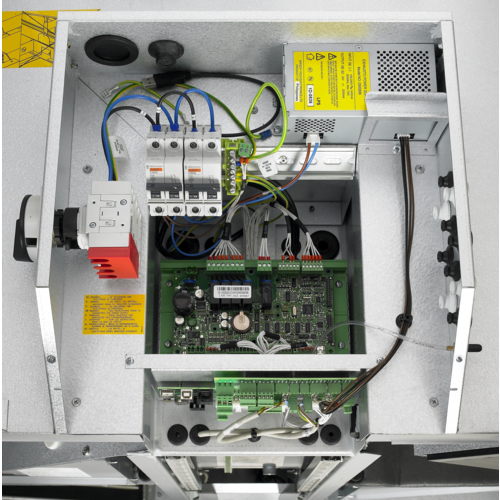

- EXact2, advanced control system

In principle, EXHAUSTO VEX units are designed for use in comfort ventilation - i.e. under ordinary operating conditions.

Where ventilation solutions are required for rooms with high air humidity - e.g. due to humidification, we recommend you make a test calculation with one of our calculation programs. If the calculation shows a risk of condensation after the heat exchanger, an assessment must be made whether the operating conditions can be changed, or whether the unit must be modified to allow condensate to drain off. This is particularly relevant for VEX100CF.

Contact EXHAUSTO for advice on this.

| References | Max. Total efficiency (A-D) (%) | Efficiency level requirements | ECO efficiency level during optimal operating point | Overload protection |

|---|---|---|---|---|

| VEX350H | 60 |

62N (2015) |

74,4N |

Built-in |

| VEX360H | 57,1 |

62N (2015) |

67,2N |

Built-in |

| VEX370H | 60,4 |

62N (2015) |

66,6N |

Built-in |

Conditions:

- Density = 1.2 kg/m3

- Pressure ratio < 1.11

- other points in acc. with EC327/2011 (see product instructions)

| References | Voltage input | Regulation | Control signal with control system | Control signal with third party control system | Fluid temperature (air) | Ambient temperature range |

|---|---|---|---|---|---|---|

| VEX350H | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX360H | 1 x 230 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

| VEX370H | 3 x 400 V |

Variable via motor control (MC) |

Modbus |

0-10 V DC |

-40°C....+40°C |

-30°C....+50°C |

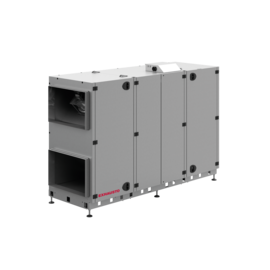

| References | A (mm) | B (mm) | C (mm) | Weight (kg) | Weight for transport |

|---|---|---|---|---|---|

| VEX350H | 2632 |

945 |

1904 |

635 |

Heat exchanger section: 260 kg Fan section (qty. 2): 2 x 150 kg Base: 75 kg |

| VEX360H | 2932 |

945 |

1904 |

702 |

Heat exchanger section: 310 kg Fan section (qty. 2): 2 x 156 kg Base: 80 kg |

| VEX370H | 3268 |

1366 |

1904 |

1018 |

Heat exchanger section: 310 kg Fan section (qty. 2): 2 x 156 kg HCW-I heating coil (integrated): 58 kgBase: 80 kg |

MECHANICAL PERFORMANCE:

According to ds/en 1886 and certified by Eurovent:

- Structural strength: D1 (M)

- Air tightness at negative pressure of -400 Pa: L1 (M)

- Air tightness at positive pressure of +700 Pa: L1 (M)

- Filter bypass leakage: F9 at negative and positive pressure

- Thermal transmittance: T2 (M)

- Thermal bridging factor: TB3

The cabinets are made of Aluzink AZ185 class C4 according to EN/ISO 12 944-2 and insulated with 50 mm mineral wool. This results in a low noise level to the surroundings/installation room.

The panel construction minimizes the formation of cold bridges in the unit.

The motor sections are mounted in vibration dampers, which means less noise and vibration in the ducts, and there is no need to install flexible connections between the unit and the duct system.

The motor sections are retractable for easier service.

The motors are of the EC type with very high efficiency, meeting the requirements of the EcoDesign directive.

EXstream performance

The unit is equipped with EXHAUSTO's EXstream fan wheel, one of the market's leading fan wheels in terms of low energy consumption and low noise levels.

The fan wheel's rotation speed and number of blades are optimized so that noise from the "blade frequency" lies in the 500 Hz band. This means that fewer/smaller sound dampers are needed than usual, as it is cheaper to dampen the noise at 500 Hz than at 125 Hz/250 Hz, where the blade frequency normally lies.

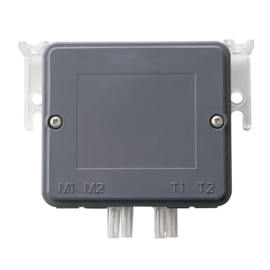

The easily accessible connection box with built-in switch disconnector and control system fuses ensures easy access for connecting and service.

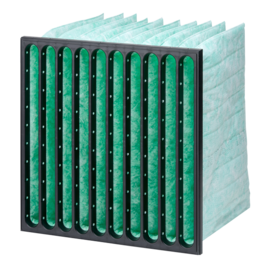

VEX350-360-370 series can be supplied with panel filters and bag filters.

Panel filters: Coarse 85% (M5) or ePM1 55% (F7)

Bag filters: ePM10 60% (M5) or ePM1 60% (F7)

Included as standard is a mounting base with feet, which has an adjustable height of 130 - 160 mm.

The unit is assembled at the bottom using the base and via suitcase fittings at the top.

VEX350/360 are modular units, which means they are supplied in sections, so that the units can be transported through door openings as small as 900 x 2000 mm. The units can also be ordered as SPLIT models if there is insufficient room to transport them in sections.

VEX370 is also available as a modular construction and can be supplied in two different spilt versions.

SPLIT 1: The fan sections are supplied ready for operation but the heat exchanger section is not sealed and can be further split into two sections, so that all four sections can be transported through door openings of 900 x 2,000 mm.

SPLIT 2: For internal transport through smaller door openings order the VEX370 SPLIT 2 version. The whole unit is supplied not sealed and can be split into smaller sections so that it may be transported internally and then assembled on site by certified personnel.

The design of the units means that in transitional periods and during summer, air can be led around the heat exchanger, via the bypass when their is reduces demand or no demand for heat recovery. The unit has a bypass on both the extract air and supply air side. Extract air and outdoor air is filtered during summer and winter operation.

During summer time, operating without heat/cold recovery, both the outdoor air and the extract air is led around the heat exchanger via the bypass. This reduces internal pressure loss and the system uses less power for the ventilators and reduces the SFP value. In summer time, if cooling recovery is selected via the EXact2 control system, both air streams will be fed through the heat exchanger.

During wintertime operation with heat recovery, extract air enters at the top and is lead vertically down through the counterflow heat exchanger with any condensed water. The outdoor air enters from the bottom and runs up through the heat exchanger – i.e. a counter flow.

In the given example, the specific power consumption is reduced from 2000 J/m3 to 1823 J/m3 on average over the year. The average specific power consumption can be used in energy framework calculations. The reduction corresponds to a saving of about 9%, a not insignificant saving. The calculation is also highly dependent on the assumptions and should be calculated in each case using the product selection program EXselectPRO.

In the above example for residential ventilation, the assumptions were:

- Exhaust air temperature/humidity: 22°C / 33% RH

- Desired supply air temperature: 20°C

- Temperature efficiency: 80%

- Cooling recovery: Active

Energy calculations depend heavily on the current situation, such as expected exhaust air and desired supply air temperature. The energy consumption for de-icing is highly dependent on the humidity of the exhaust air. In residential buildings, icing of the heat exchangers typically begins at an outside temperature around -4°C to -6°C, whereas in offices there is usually no icing.

To minimize energy consumption for de-icing, it is important that ice formation is detected based on pressure drop measurement across the heat exchanger, as is the case with VEX350/VEX360/370.

Products and accessories references

Documents

-

VEX360 Ecodesign DeclarationCertificates and declarations342 KB

-

VEX370 Ecodesign DeclarationCertificates and declarations342 KB

-

VEX100-VEX100CF-VEX200-VEX330-350-360-370 Outdoor InstructionInstructions3 MB

-

VEX, Siphon - pressure side, installation guideInstructions641 KB

-

VEX, assembly on a METU railInstructions358 KB

-

VEX350/360/370 Transport instructionTechnical & Business documentation2 MB

-

VEX340-370, order formTechnical & Business documentation280 KB

-

VEX350H-X without controls, mechanical instructionInstructions4 MB

-

VEX360H-X without controls, mechanical instructionInstructions4 MB

-

VEX350H with EXact2, mechanical instructionInstructions4 MB

-

VEX360H with EXact2, mechanical instructionInstructions4 MB

-

VEX370 with HCW water heating coil and EXact2, mechanical instructionInstructions7 MB

-

VEX370H-Xwith HCW water heating coil without controls, mechanical instructionInstructions5 MB

-

VEX350-360-370H with EXact2, electrical instructionInstructions2 MB

-

VEX350-360-370H-X without controls, electrical instructionInstructions2 MB

-

EXact2 HMI2 for VEX300, instructionInstructions6 MB

-

EXact2 HMI2 for VEX300, menu guideInstructions1 MB

-

VEX370 disassembly of heating coilTechnical & Business documentation1 MB

-

VEX370 mounting and sealing of heat exchange sectionTechnical & Business documentation3 MB

-

VEX350/360 Retrofit Filter Kit installation guideInstructions6 MB

-

VEX370 Retrofit Filter Kit bag filterInstructions5 MB