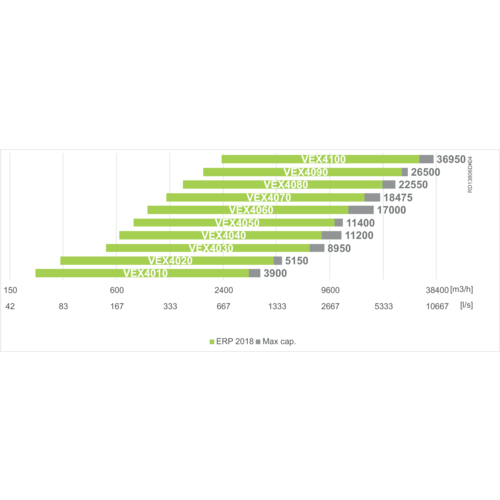

VEX4000 - ROTARY HEAT EXCHANGER

Modul

Furthermore humidity from exhaust can be transferred to supply air

At high air volumes the rotating heat exchanger is a compact and sustainable solution.

The rotor heat exchanger works down to -20 degrees Celcius without any de-icing and no need for handling dondensation.

Select between 4 types:

- Condensing rotor - Suitable for ventilation systems without humidification and cooling. (Standard)

- Enthalpy rotor - suitable for ventilation systems with humidification and without cooling. (Option)

- Sorption rotor - suitable for ventilation systems with humidification and cooling. (Option)

- Coated condensing rotor - suitable for particularly corrosive environments. (Option)

Selection of a non-standard rotor will probably entail a longer delivery time.

Product advantages

- High degree of temperature efficiency

- Compact solution for large air volumes

- Humidity transfer means no dry indoor climate

- De-icing not necessary down to -20 degrees Celcius

- No need for handling of condensation

- Available with ALC, patented automatic leakage control

- Choice of 4 rotor types (condensing, enthalpy, sorption, coated condensing for corrositive environment)

- Choice of different wave heights

- Supplied with and without blow-clean section (Blow-clean section required in combination with ALC)

The rotary heat exchanger can give a temperature efficiency of up to 90 %.

In addition, humidity from the extract air can be transferred to the supply air, thus ensuring optimum air quality in practically all application areas.

All ER modules are supplied ready-fitted with a drive unit and rotation monitor and are integrated with EXcon control.

However, the rotor control system can also be used in conjunction with other control systems.

The drive system consists of a belt moving round the periphery of the rotor, while the motor control system ensures variable rotor speed, depending of the heat recovery requirement. The system is only controlled with a 0–10 V signal, which regulates the speed of the motor (for other control systems, but incl. rotor control). This means that the drive system is not dependent on a particular control system.

The rotor is solidly seated in the frame construction, and minimal leakage is guaranteed by lip and brush seals.

EXcon uses ModBus for rotor control, which comprises:

-

- Rotation monitoring with external rotation sensor

- Alarm relay

- De-icing via differential pressure measurement

- Cold recovery

The rotors can be supplied with an air flushing section, to help minimise the transfer of contaminated air from extract air to supply air. If the flushing function is selected, it will be integrated. (For this it is essential that the static pressure on the supply air side is higher than on the exhaust side).

| VEX modele | Height (mm) | Length (mm) | Width (mm) |

|---|---|---|---|

| VEX4010 | 1309 | 720 | 1055 |

| VEX4020 | 1309 | 720 | 1275 |

| VEX4030 | 1499 | 610 | 1549 |

| VEX4040 | 1599 | 610 | 1630 |

| VEX4050 | 1744 | 610 | 1755 |

| VEX4060 | 2069 | 720 | 1930 |

| VEX4070 | 2069 | 720 | 2115 |

| VEX4080 | 2344 | 720 | 2325 |

| VEX4090 | 2594 | 720 | 2625 |

| VEX4100 | 2874 | 720 | 2895 |