FSB

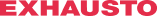

Ventilation box fan

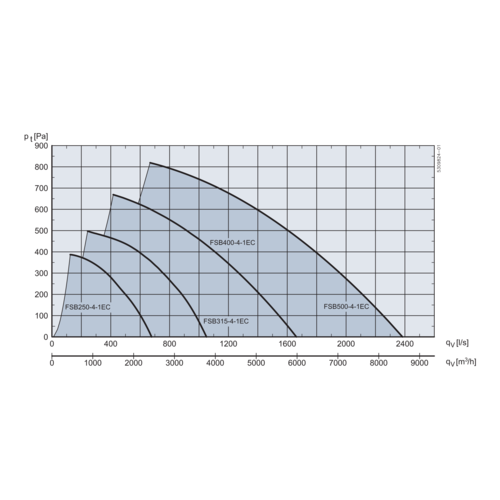

As a general operations fan, FSB is a low-energy box fan, as it is fitted with an EC motor and fan impellers with backward curved blades. FSB is available in 4 sizes, covering the capacity range 350 - 7 300 m³/h.

Product advantages

- Certified combustion gas fan

- Operation and evacuation fan F400/2H

- Low energy consumption

- Low operating costs

- Longer service intervals

- Low sound level

- Backward curved blades

| References | Conditions | Insulation material |

|---|---|---|

| FSB25041EC2 | ||

| Conditions: * I is the maximum absorbed current throughout the control range - or the full load current if this is larger ** P1 is the maximum absorbed power from the mains supply, where P2 is the motor's nominal output. Stated data are for t = 20°C Density = 1.2 kg/m3 Gas temperature: min. -12°C, max. +80° C Ambient temperature: Max. +40° C Pressure ratio: < 1,11 other points in acc. with EC327/2011 - see product instructions |

||

| FSB31541EC2 | ||

| Conditions: * I is the maximum absorbed current throughout the control range - or the full load current if this is larger ** P1 is the maximum absorbed power from the mains supply, where P2 is the motor's nominal output. Stated data are for t = 20°C Density = 1.2 kg/m3 Gas temperature: min. -12°C, max. +80° C Ambient temperature: Max. +40° C Pressure ratio: < 1,11 other points in acc. with EC327/2011 - see product instructions |

||

| FSB40041EC2 | ||

| Conditions: * I is the maximum absorbed current throughout the control range - or the full load current if this is larger ** P1 is the maximum absorbed power from the mains supply, where P2 is the motor's nominal output. Stated data are for t = 20°C Density = 1.2 kg/m3 Gas temperature: min. -12°C, max. +80° C Ambient temperature: Max. +40° C Pressure ratio: < 1,11 other points in acc. with EC327/2011 - see product instructions |

||

| FSB50041EC2 | ||

| Conditions: * I is the maximum absorbed current throughout the control range - or the full load current if this is larger ** P1 is the maximum absorbed power from the mains supply, where P2 is the motor's nominal output. Stated data are for t = 20°C Density = 1.2 kg/m3 Gas temperature: min. -12°C, max. +80° C Ambient temperature: Max. +40° C Pressure ratio: < 1,11 other points in acc. with EC327/2011 - see product instructions |

| References | Max. Total efficiency (A-D) (%) | Ventilation energy class - Average climate | Efficiency level requirements | ECO efficiency level during optimal operating point | EC motor | Optimum operating point | Nominal speed (RPM) | Power supply | Overload protection | Engine power (kW) |

|---|---|---|---|---|---|---|---|---|---|---|

| FSB25041EC2 | 68,4 |

D |

64, N(2015) |

96,8 |

Optimalt driftspunkt:

|

1400 |

1x230 - 50 Hz |

Indbygget i motorstying |

0,18 |

|

| 0,684 |

D |

64, N(2015) |

96,8 |

EC motor with integral VSD |

Optimal operating point: Absorbed power Airflow Total pressure Rpm 164 W 1354 m³/h 298 Pa 1443 rpm |

1400 |

1x230 - 50 Hz |

Integrated in motor control |

0,18 |

|

| FSB31541EC2 | 69,0 |

D |

64, N(2015) |

92,8 |

Optimalt driftspunkt:

|

1400 |

1x230 - 50 Hz |

Indbygget i motorstying |

0,37 |

|

| 0,69 |

D |

64, N(2015) |

92,8 |

EC motor with integral VSD |

Optimal operating point: Absorbed power Airflow Total pressure Rpm 335 W 2173 m³/h 383 Pa 1417 rpm |

1400 |

1x230 - 50 Hz |

Integrated in motor control |

0,37 |

|

| FSB40041EC2 | 71,6 |

D |

64, N(2015) |

95 |

Optimalt driftspunkt:

|

1435 |

1x230 - 50 Hz |

Indbygget i motorstying |

0,75 |

|

| 0,716 |

D |

64, N(2015) |

95 |

EC motor with integral VSD |

Optimal operating point: Absorbed power Airflow Total pressure Rpm 375 W 2868 m³/h 337 Pa 1195 rpm |

1435 |

1x230 - 50 Hz |

Integrated in motor control |

0,75 |

|

| FSB50041EC2 | 71,5 |

D |

64, N(2015) |

89,6 |

Optimalt driftspunkt:

|

1420 |

1x230 - 50 Hz |

Indbygget i motorstying |

1,1 |

|

| 0,715 |

D |

64, N(2015) |

89,6 |

EC motor with integral VSD |

Optimal operating point: Absorbed power Airflow Total pressure Rpm 824 W 4252 m³/h 499 Pa 1261 rpm |

1420 |

1x230 - 50 Hz |

Integrated in motor control |

1,1 |

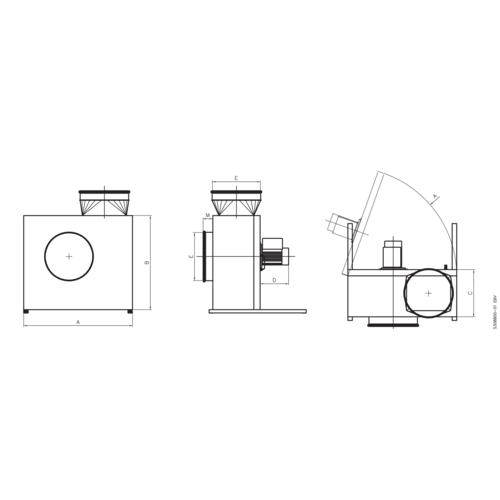

The box vfan can be mounted in various positions. Note, however, that the fan must not be positioned with the motor turned downwards. Standard installation: A Alternative installation options: B, C and D During installation, consideration must be given to opening the door for servicing and for access to door screws (see dimensions table on pages 7 and 15 in the product instructions where opening radius R is given). There should also be enough space to insulate the ducts. In installation options B and D, with the door facing upwards, special fittings must be used to hold the door(accessory). The box fan should not be screwed onto the supporting base. The base must be stable and vibration free, with no sagging.

| References | A (mm) | B (mm) | C (mm) | G (mm) | E Ø (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| FSB25041EC2 | 785 |

625 |

325 |

800 |

250 |

52 |

| 785 |

625 |

325 |

800 |

250 |

52 |

|

| FSB31541EC2 | 785 |

675 |

355 |

800 |

315 |

57 |

| 785 |

675 |

355 |

800 |

315 |

57 |

|

| FSB40041EC2 | 895 |

775 |

390 |

800 |

400 |

73 |

| 895 |

775 |

390 |

800 |

400 |

73 |

|

| FSB50041EC2 | 990 |

880 |

425 |

850 |

500 |

88 |

| 990 |

880 |

425 |

850 |

500 |

88 |

| References | Frequency (Hz) | Max. power | Max. current (A) | Engine power (kW) | ErP-effektivitetsgrad i optimalt driftspunkt | Motor Amp/kW |

|---|---|---|---|---|---|---|

| FSB25041EC2 | 50 |

0,17 |

1,2 |

0,18 |

96,8 |

1,2 / 0,18 |

| 0,17 |

1,2 |

0,18 |

96,8 |

1,2 / 0,18 |

||

| FSB31541EC2 | 50 |

0,35 |

2,2 |

0,37 |

2,2 / 0,37 |

|

| 0,35 |

2,2 |

0,37 |

92,8 |

2,2 / 0,37 |

||

| FSB40041EC2 | 50 |

0,67 |

4,5 |

0,75 |

95 |

4,5 / 0,75 |

| 0,67 |

4,5 |

0,75 |

95 |

4,5 / 0,75 |

||

| FSB50041EC2 | 50 |

1,23 |

8,5 |

1,1 |

89,6 |

8,5 / 1,1 |

| 1,23 |

8,5 |

1,1 |

89,6 |

8,5 / 1,1 |

| Ventilation energy class - Average climate |

|---|

| D |

FSB box fans are made from Aluzinc® AZ185 class C4 in accordance with EN/ISO12944-2 and insulated with 50-mm mineral wool. FSB has been tested and approved both as a general operations fan and as an evacuation fan F400/2h in accordance with EN12101-3:2015

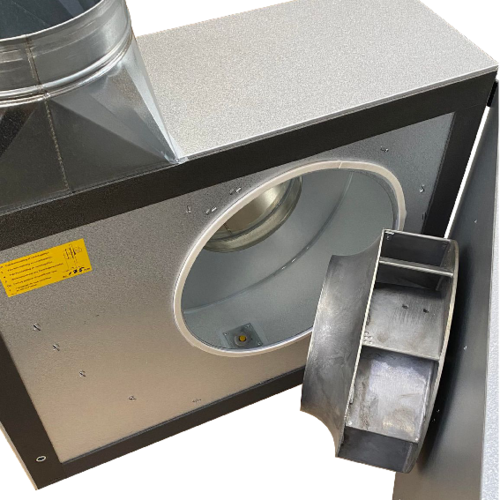

The fan impeller is a B-impeller made from cast aluminium. It has backward curved blades, thus ensuring low energy consumption and the further advantage that less dirt is attracted, with impaired impeller efficiency as a result.

The spigots on FSB have rubber gaskets, with a transition piece on the extract side specially developed for minimum pressure drop.

To minimise noise and vibration, the box fan is fitted as standard with efficient vibration dampers mounted on brackets.

The FSB box fan is mounted with split hinges, which enable the door to be removed for installation and servicing, even in very confined conditions or for transport to difficult locations.

The FSB box fan is designed to transport air with an air humidity of less than 80% RH. FSB is available as a special model with a condensation outlet for air with over 80% RH