TGR

By mounting an extractor fitting in the room, you get an optimum air handling solution with minimum pressure drop and low sound levels, even at high airflow rates.

Externally, TGR is constructed from a galvanised sheet, and underneath, a 50-mm mineral wool, fine-mesh fabric and an internal galvanised perforated sheet

Product advantages

- Supplied with perform or zinc flashing

- Available in sizes corresponding to DTH – in 3 different lengths

- Insulated against sound and condensation

TGR is supplied as standard in 3 lengths and 6 sizes with PERFORM flashing appropriate to the roof pitch. TGR can also be supplied with zinc flashing or without flashing. Must be stated on order.

PERFORM comes as standard in black, but grey and red can be ordered at no extra cost.

| References | Max. roof pitch |

|---|---|

| TGR160-600 | 30 |

| TGR160-900 | 45 |

| TGR160-1200 | 60 |

| TGR200-600 | 30 |

| TGR200-900 | 45 |

| TGR200-1200 | 60 |

| TGR250-600 | 20 |

| TGR250-900 | 45 |

| TGR250-1200 | 60 |

| TGR315-600 | 20 |

| TGR315-900 | 40 |

| TGR315-1200 | 55 |

| TGR400-600 | 15 |

| TGR400-900 | 35 |

| TGR400-1200 | 50 |

| References | L1 (mm) | Ø C (mm) | Ø C1 |

|---|---|---|---|

| TGR160-600 | 600 |

268 |

160 |

| TGR160-900 | 900 |

268 |

160 |

| TGR160-1200 | 1200 |

268 |

160 |

| TGR200-600 | 600 |

305 |

200 |

| TGR200-900 | 900 |

305 |

200 |

| TGR200-1200 | 1200 |

305 |

200 |

| TGR250-600 | 600 |

370 |

250 |

| TGR250-900 | 900 |

370 |

250 |

| TGR250-1200 | 1200 |

370 |

250 |

| TGR315-600 | 600 |

440 |

315 |

| TGR315-900 | 900 |

440 |

315 |

| TGR315-1200 | 1200 |

440 |

315 |

| TGR400-600 | 600 |

510 |

400 |

| TGR400-900 | 900 |

510 |

400 |

| TGR400-1200 | 1200 |

510 |

400 |

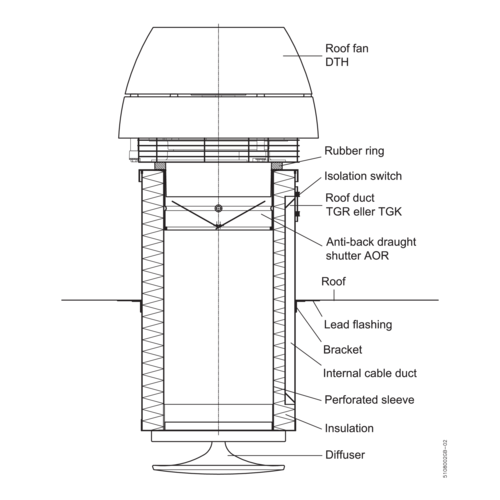

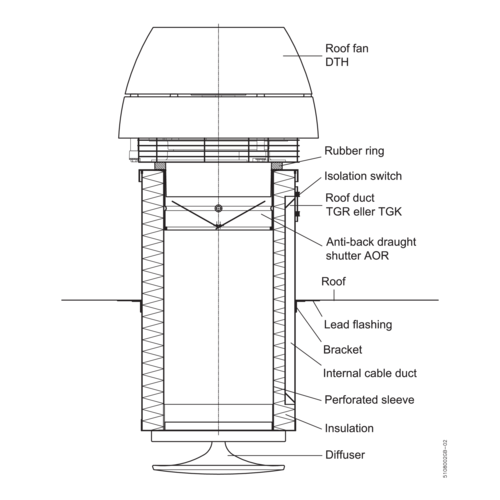

The roof vent is insulated for sound and condensation. To avoid transfer of vibrations to the roof vent, a rubber ring is mounted on the fan.

The roof vent has been designed to take an electric cable via the integral cable duct. The installation cable is inserted in the cable duct at the bottom and drawn up by the safety switch, which is not normally an EXHAUSTO delivery. The safety switch is mounted on the control panel as shown in the guide 3004346.

As standard the roof vents are mounted with anti-backdraught shutter AOR, but can also be specially ordered without this.

When cleaning the roof vent and/or connector duct, the anti-backdraught shutter is easily detachable without use of tools.

The anti-backdraught shutter AOR opens when the fan is in operation.

Make a hole in the roof about 30 mm larger than the vent, and loosen overlying tiles/panels, sliding them upwards to permit insertion of flashing.

Carefully position the vent on the roof with the flashing level with the roof tiles. Fix the brackets to the vent, lifting it by about 5 mm when the brackets are subsequently fixed to the rafters. This will ensure that the whole weight rests on the brackets.

Roll out the flashing and knock it carefully into shape (with PERFORM, a rubber hammer or sandbag must be used). Replace overlying tiles/panels over the flashing.

An EXHAUSTO roof fan, roof vent and diffusor at the base of the roof vent will provide an optimum air handling solution for the minimum of space, for example on flat or sloping roofs with a short distance to the extraction point.

If there is a long distance between the roof vent and the extractor fitting, an extension can be formed with spiral tube or similar, with a duct fitting directly attached to the base of the roof vent.

If ventilation is required from several locations, a spiral tube can be mounted to the base of the roof vent with duct fittings or T-pieces, sound locks etc. connected to a complete ducting system to the desired locations.