aDCV – adaptive, demand-controlled ventilation

Airflow varies as required via patented adaptive pressure control

How constant pressure controlled ventilation can be further optimised

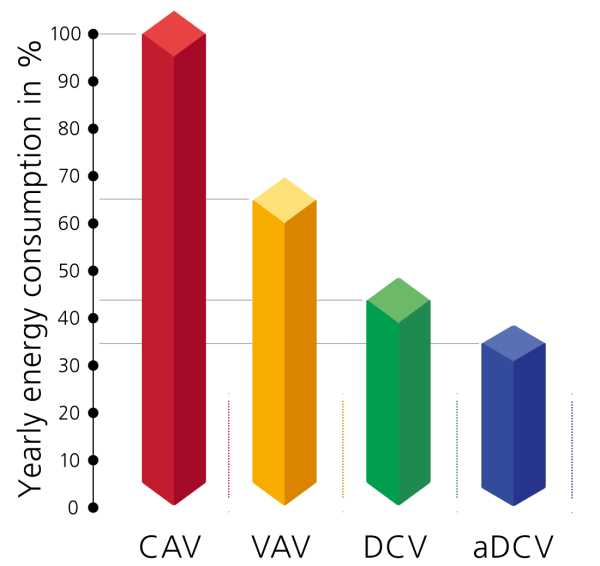

Thanks to the patented adaptive pressure control, up to 43% savings on energy costs can be achieved – compared to a system with constant pressure control (VAV), and up to 19% compared to a demand-controlled system with constant pressure control (DCV).

The patented adaptive pressure control provides the possibility to optimize operation with constant pressure regulation of ventilation systems with variable airflows.

More benefits of patented adaptive pressure control

Use aDCV and achieve energy savings with lower pressure drop and lower noise level

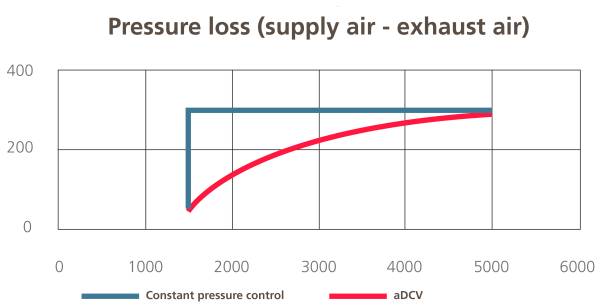

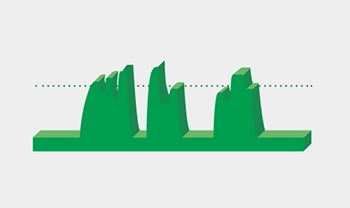

With constant pressure regulation (VAV), a constant pressure is provided through the ventilation system at all air volumes (Fig.: 1 – blue line).

With variable volume flow systems (VAV) - e.g. zone control via CO2 or humidity, however, the ventilation system requires less pressure loss in the system at a lower air volume (Fig.:1 – red line) - and this is precisely possible with aDCV.

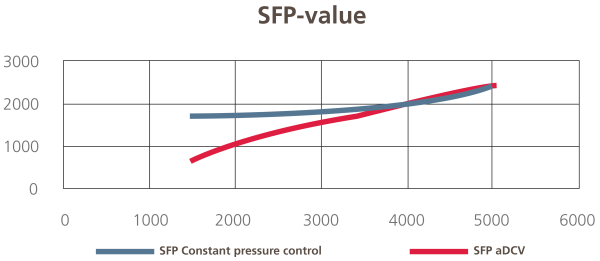

SFP value

aDCV – the patented adaptive pressure control reduces the pressure of the ventilation system when the airflow decreases and only provides the necessary pressure.

As a result, the ventilation system – especially in partial load situations – consumes significantly less energy than with constant pressure control (Fig. 2 – red line).

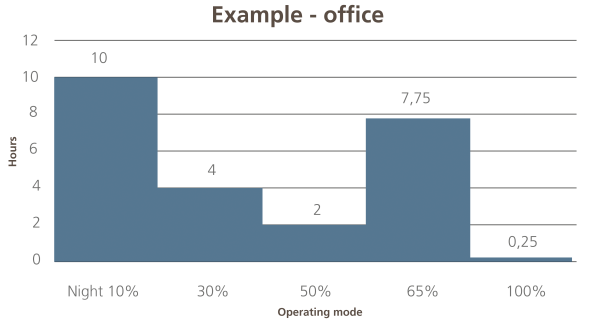

Example: School/office building

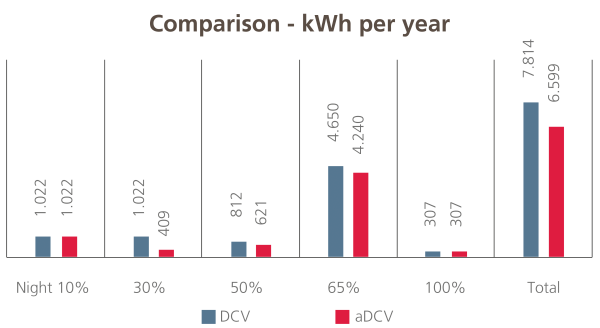

Here is a typical example of the ventilation requirement during the day. At night, the ventilation system goes into “night mode” and a traditional DCV system will reduce the pressure to e.g. 50 Pa. During this period, the energy consumption of DCV and aDCV will be the same. During the day, when the ventilation requirement will typically vary in relation to activity in the different rooms, operation with aDCV will reduce the pressure and thus the pressure loss and thus save energy in relation to DCV.

Below is a comparison between operation with DCV and aDCV, which shows a saving of approx. 16% on an annual basis. Our calculations have shown that the savings by controlling the ventilation with aDCV instead of DCV will typically be 15–20%.

If we compare aDCV with CAV and VAV, the savings will be even greater.

We recommend aDCV when:

- Rooms are used periodically

- Number of people varies

- The ventilation is regulated using CO2 or PIR sensors with VAV dampers in the individual rooms.

- Offices, teacher rooms, meeting rooms, etc.

Examples of this are:

Offices, teaching rooms, meeting rooms, etc.

The solution - pros and cons

Benefits

- Airflow follows load in rooms as with DCV, but additional energy savings are achieved as the duct pressure is also lowered.

- Fully automatic control

- Fewer weekly schedule updates

- Control principle with lowest energy consumption

- Good alternative to a full zone control system

Cons

- Expensive installation