The strongest ventilation program on the market

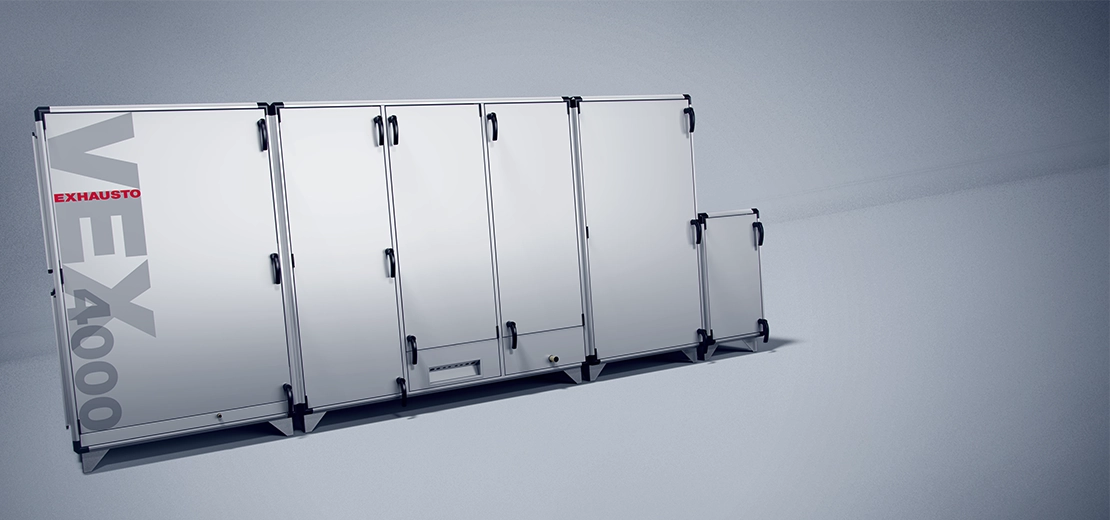

VEX4000 - countless combinations, always a solution

6 good reasons to choose VEX4000

There are many reasons to choose VEX4000 for your next project - here are six of them

6 good reasons

Extremely energy efficient

VEX4000 has an efficiency of over 90% (with condensation) and patented adaptive pressure control that further reduces energy consumption.

Low noise emission

One of the quietest fan impellers on the market combined with EC motors gives an extremely low noise level.

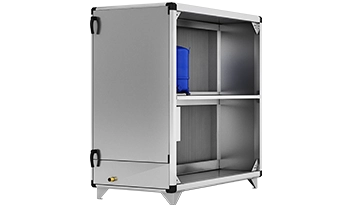

Small and compact design

Compact, modular design, even available as a SPLIT solution for narrow access routes.

Simple installation

Your unit is assembled either before or after delivery with assembly brackets and detailed assembly instructions. Assembling a ventilation unit has never been easier!

Easy configuration

With the unique EXselectPRO design program, you can put together your own unit with the modules and functions required in your project.

Reversible heat pump

VEX4000 is available with an integrated reversible heat pump. Here you get ventilation, heating and cooling in one unit; simple, reliable and highly energy-efficient.

Unique project planning with

Whatever your project, VEX4000 is up to the task, and with our design program EXselectPRO you can combine and assemble your ventilation system the way you want. At the same time, the program provides you with detailed technical data, dimensional sketches and energy calculations and labels. Easy and straightforward!

Installation has never been easier

- Unit delivered assembled

If the unit is delivered assembled, EXHAUSTO ensures that all modules are correctly connected to each other and assembled on a base frame. - Modules delivered separately

In many cases it can be an advantage to receive the modules individually, for example if the modules have to pass through doors or up stairs. That's why VEX4000 is designed in a way that makes it very easy to assemble. - SPLIT solution

The unit is delivered disassembled in so-called "Flat-Pack" so that even large units can be transported into narrow access areas.

Heat pump in combination with ventilation

Energy efficiency and low energy consumption requirements for ventilation solutions have increased the focus on combining heat recovery with an integrated heat pump. By combining ventilation, heating and cooling in one unit, you get a solution that is both highly energy efficient and far simpler than traditional cooling solutions with chillers and ducting on the roof.

With VEX4000RHP you get...

- Heating, cooling and ventilation in one integrated unit

- One factory-tested unit

- Advanced EXcon automation

- No need for additional heating/cooling installations

- Fast, simple calculation, documentation and technical data via EXselectPRO

- One supplier for the whole solution

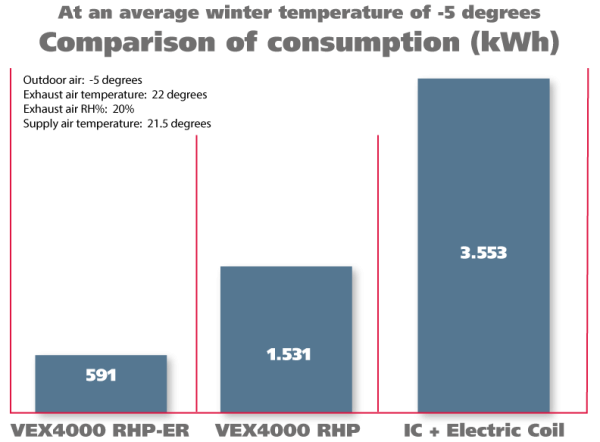

With a VEX4000RHP-ER, a rotary heat exchanger is placed between the evaporator and condenser for the lowest energy consumption and refrigeration recovery. With VEX4000RHP, the heat exchanger and heat pump are placed in separate modules, contributing to a compact solution that is easier to transport.

We assume here that the heat pump or the heat exchanger must run half of the year at 33% capacity to achieve the supply air temperature. Compared to an electrical heating coil VEX4000 RHP and VEX4000 ER-RHP reduces the heat consumption by 60%/82% respectively.

Any extra investment when purchasing a heat pump pays for itself relatively quickly. Comparison with district heating, gas, oil or other energy source will depend on price per kW.

EXHAUSTO ALC™

The patented solution to prevent the spread of disease through a rotary exchanger ventilation unit

ALC™ is a simple plug & play solution offered for VEX4000 with rotary exchanger. The solution prevents leakage and thus prevents the spread of viruses, particles and gases through the ventilation system. By activating ALCCTM, leakage is prevented by the VEX's automatic system, regardless of the current operating situation.

How ALC™ works

- A sensor measures the pressure difference between the exhaust and supply air chambers in the VEX unit.

- The automation in the unit regulates an exhaust air damper based on the pressure difference.

- This ensures that the pressure in the exhaust air chamber is always lower than in the supply air

With the automatic leakage control, the Exhaust Air Transfer Ratio (EATR) is reduced to 0%** and recirculation of airborne particles and gases, including virus particles, is eliminated. At the same time, ALC™ is an energy-efficient solution as demand-controlled operation can be done without leakage problems.

Benefits:

- A simple plug & play solution that can also be retrofitted

- Exhaust air transfer rate EATR = 0%**

- The perfect solution for hotels, educational institutions, offices, hospitals, shopping centers etc

**Tested and validated at Danish Technical University. EATR = 0% based on Eurovent "Air Leakages in Air Handling Units: Guidelines for Improving Indoor Air Quality and Correcting Performance", 2021, EN308 and EN16798-3

EXcon control system

- Advanced control for optimal operation

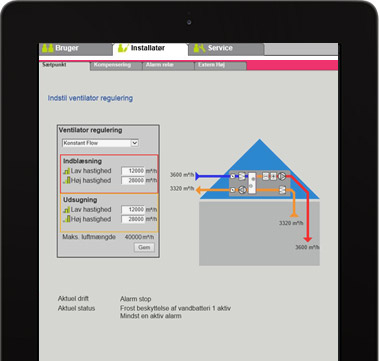

VEX4000's built-in EXcon control system controls airflow, heating and cooling, and it's up to the user to decide how and when the automation should switch between the built-in functions.

Functions built into the control system

- Night setback

- Alarm log and data log

- Control by daily, weekly or annual schedule

- Extended operation

- External forced operation with after-run

- Alarm e-mail

- Summer night cooling

- Outdoor temperature compensation

- Automatic summer/winter switching

- Zone control for four zones

- Portal solution, total monitoring of up to 5 systems with EXconautomatik

Control modes

- Constant pressure

- Constant air volume

- ConstantCO2

- Fan optimizer

- Constant motor speed

- Adaptive pressure control (Patented solution for energy optimization of VAV systems)

- External 0-10V with supply air/free air slave

- Constant pressure control with supply/exhaust air slave

- 3 levels; low, medium and high speed/pressure/airflow

Temperature regulation

- Constant supply air temperature

- Constant extract air temperature

- Constant room temperature

- Constant difference between extract and supply air

- Summer and winter compensation

- Recirculation heating (optional)

- Summer night cooling

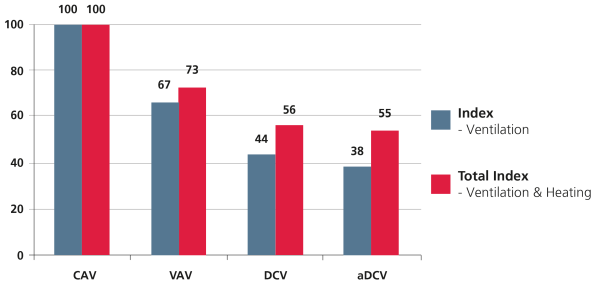

43% energyEnergy savings vs. VAV

World-class energy efficiency with patented adaptive pressure control

The VEX4000 unit comes with EXcon control system, which allows you to use EXHAUSTO's patented adaptive pressure control (aDCV). Adaptive pressure control continuously optimizes the pressure in the unit depending on the demand in the building, reducing energy consumption compared to traditional methods of pressure control (CAV, VAV, and DCV). Through the patented adaptive pressure control, up to 43%* savings on energy costs can be achieved.

*Up to 43% compared to a system with constant pressure control (VAV). Up to 20% compared to a demand-controlled system with constant pressure control (DCV)

Operate the system when you want, where you want

Setting and control via web server from PC, smartphone or tablet. Network communication supports BacNet over TCP/IP and Modbus over RS485 or TCP/IP. Communication with LonWorks can also be supported as an option.

Certified performance

VEX4000 series takes into account key industry norms and standards

EUROVENT

VEX4000 is Eurovent certified and as part of this certification, the data provided in EXselectPro is verified.

RLT

VEX4000 is RLT certified and as part of this certification, the data provided in EXselectPRO is verified.

VDI 6022

VEX4000 is designed in accordance with the German hygiene standard VDI 6022.

We can advise you on how to ensure optimal access for inspection and cleaning of your ventilation unit's sub-components and thus prevent harmful microorganisms from entering the ventilation system's air streams.

For an additional fee, you can order VEX4000 as a hygiene certified unit in accordance with VDI 6022-1.

VEX4000 - a result of experience and know-how

VEX4000 may be a future-proof series, but its development is based on our knowledge and know-how of quality products that the market has known and appreciated for decades.

In the more than 60 years EXHAUSTO has been developing and manufacturing ventilation solutions, the focus has always been on the ever-increasing demands from legislation and customers.

We have combined our know-how from the VEX100-200-300 series with the knowledge we have gained from the unit series we have since acquired - and developed the VEX4000 series, which with a capacity range from 1,050 to 36,000 m³/h and unique configuration options can solve virtually all ventilation tasks within comfort ventilation

Your expert and professional ventilation partner

Contact us for more informationAt EXHAUSTO, we never compromise on quality, and as ventilation experts with many years of specialist experience, you are not only guaranteed the best ventilation solution, but also a competent partner.

EXHAUSTO develops and manufactures high-quality products and systems for comfort ventilation in all areas of application - from offices, shops, schools and institutions to industrial buildings, hotels and hospitals.

With a focus on high efficiency and energy consumption that meets future energy requirements, EXHAUSTO is among the absolute leaders in the field.